Study on Bacteriostatic Characteristics of Lactobacillus plantarum LV02 and Optimization of Fermentation Medium

-

摘要:

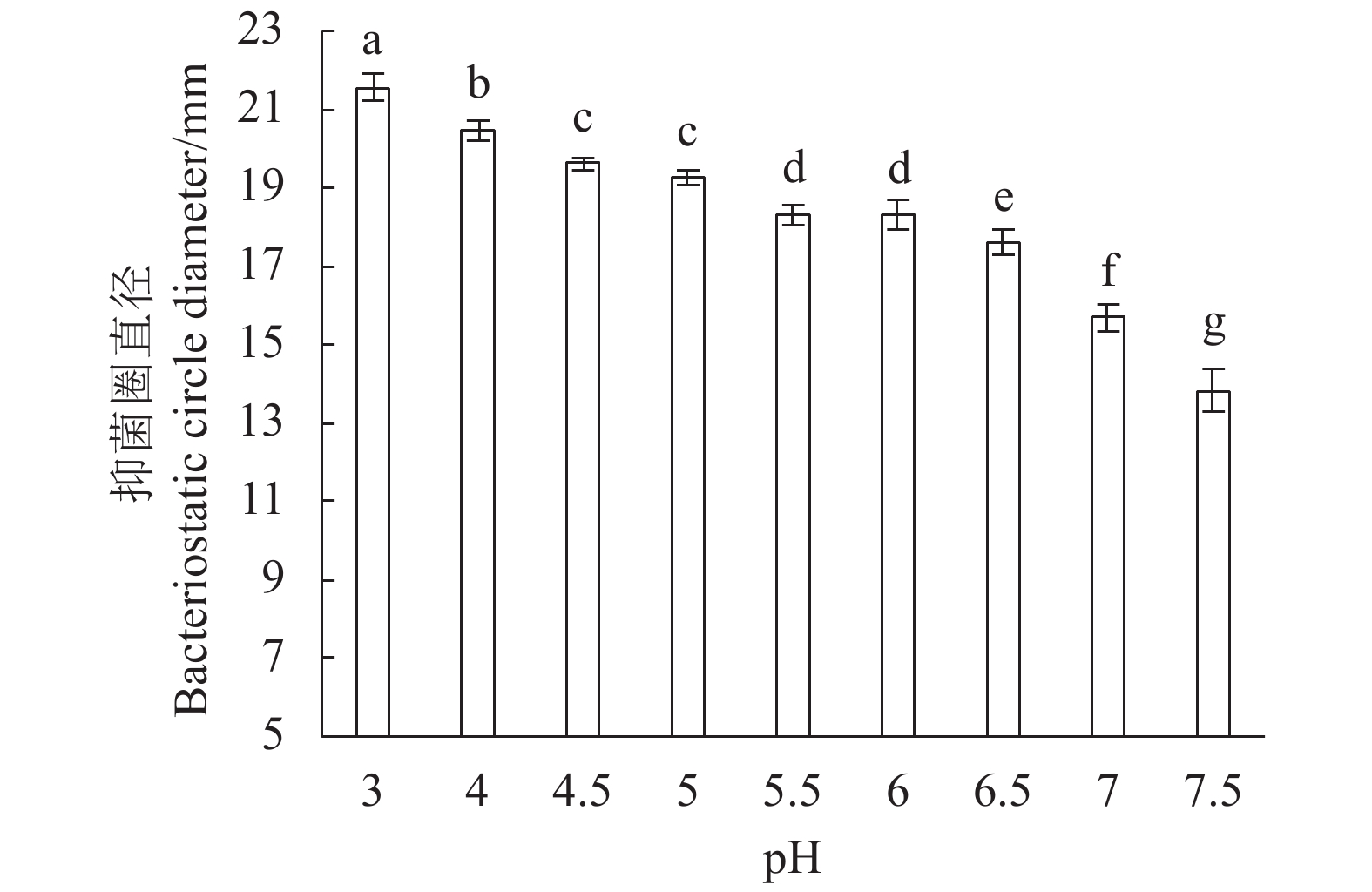

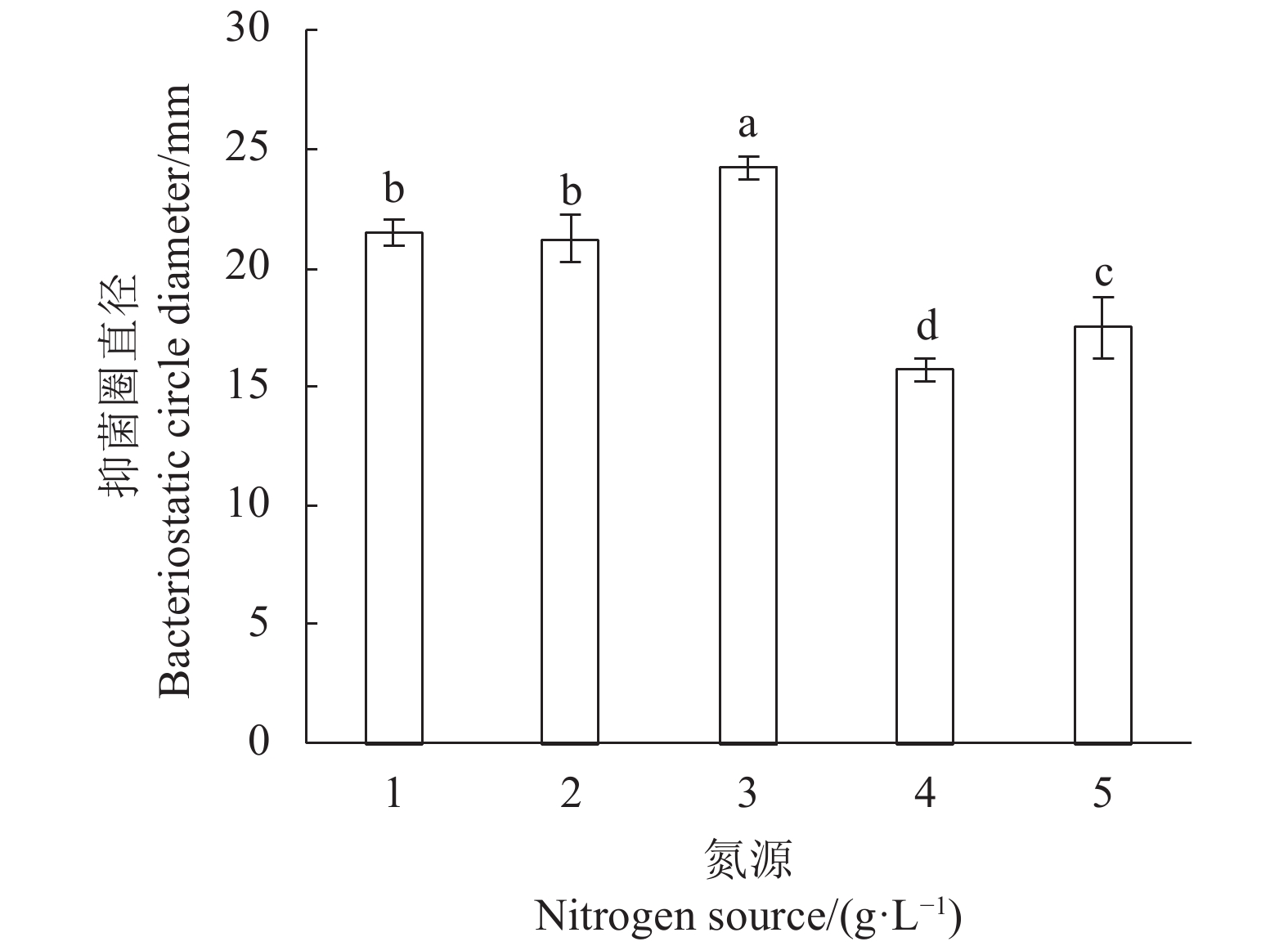

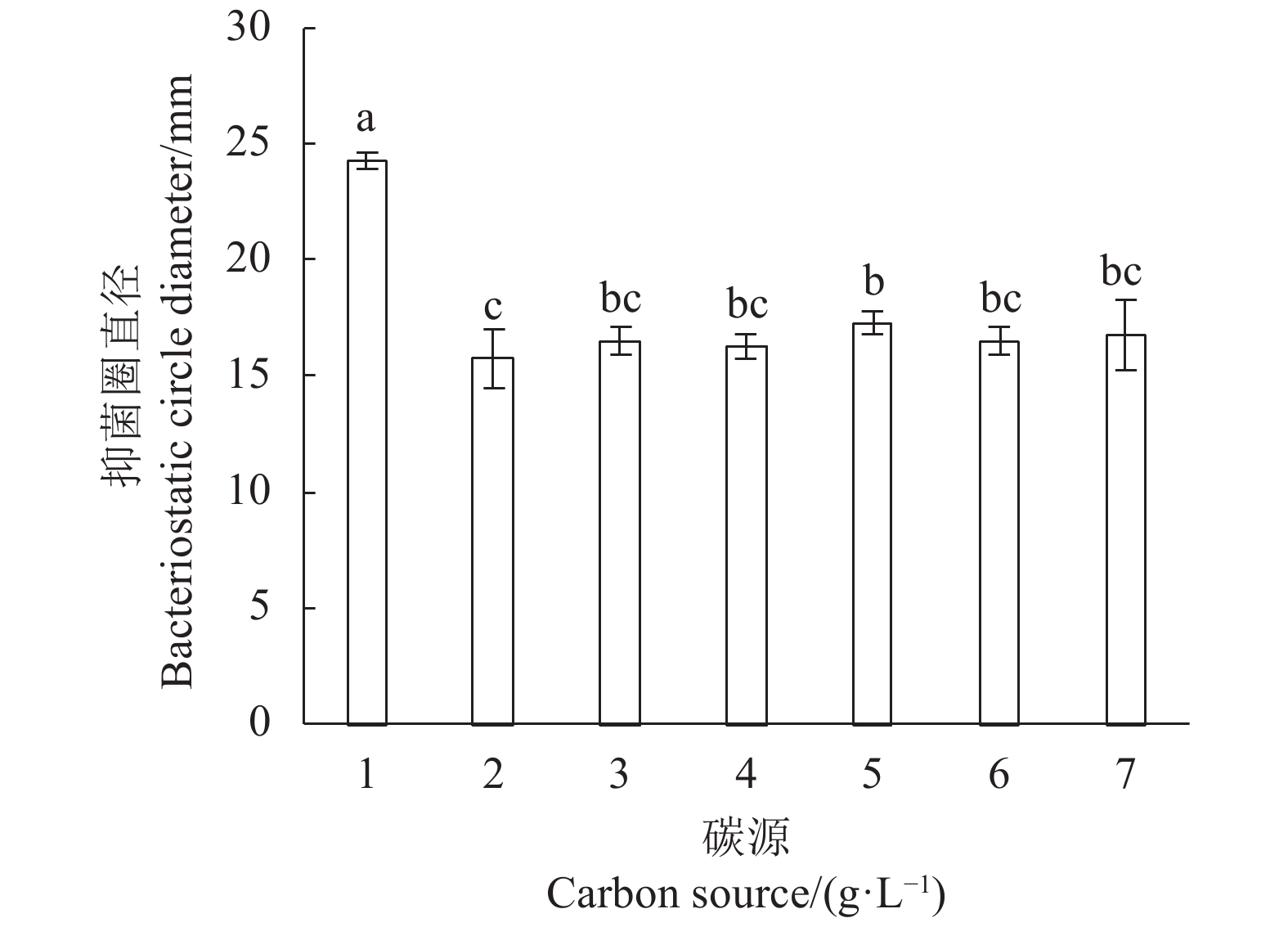

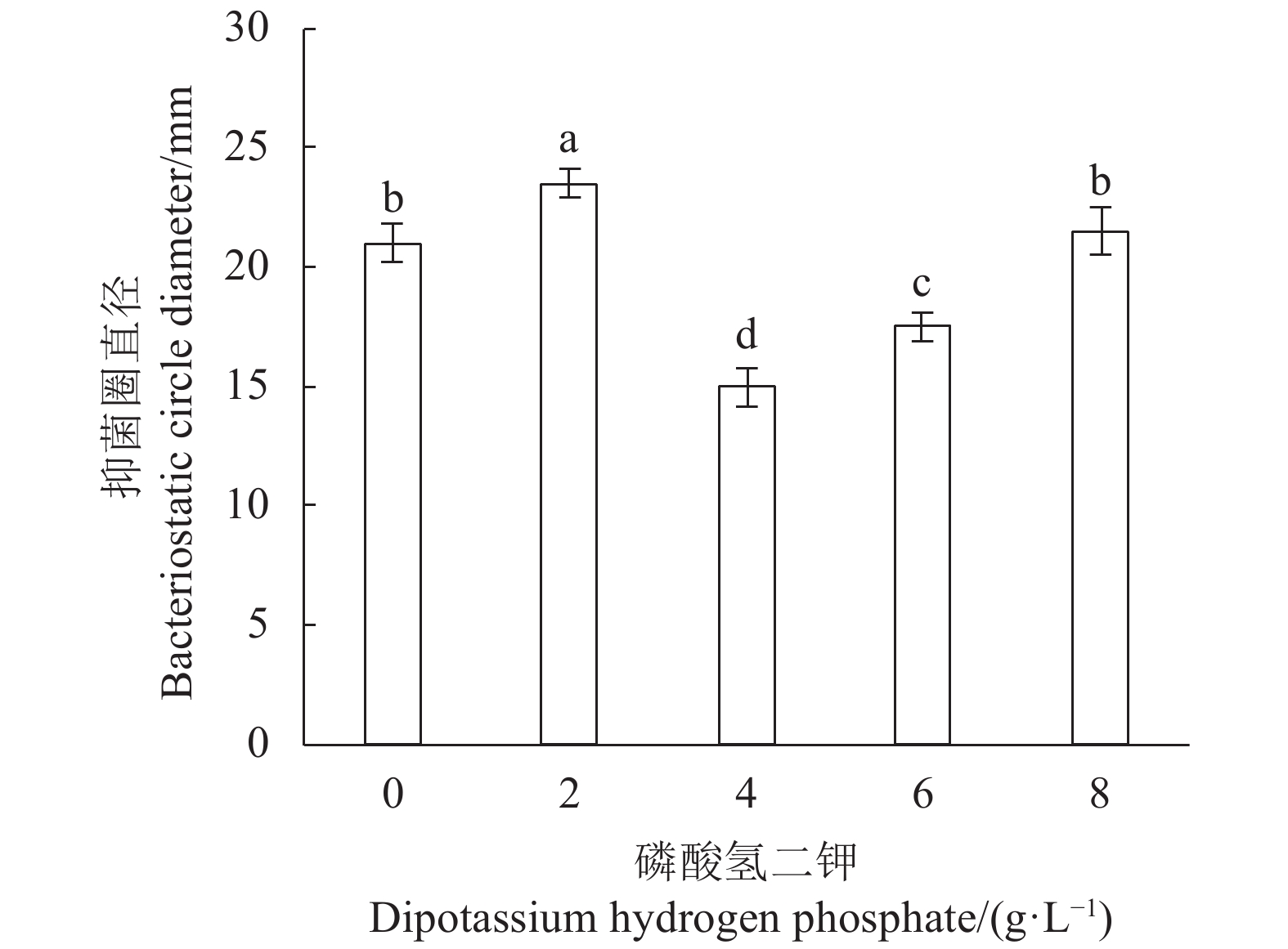

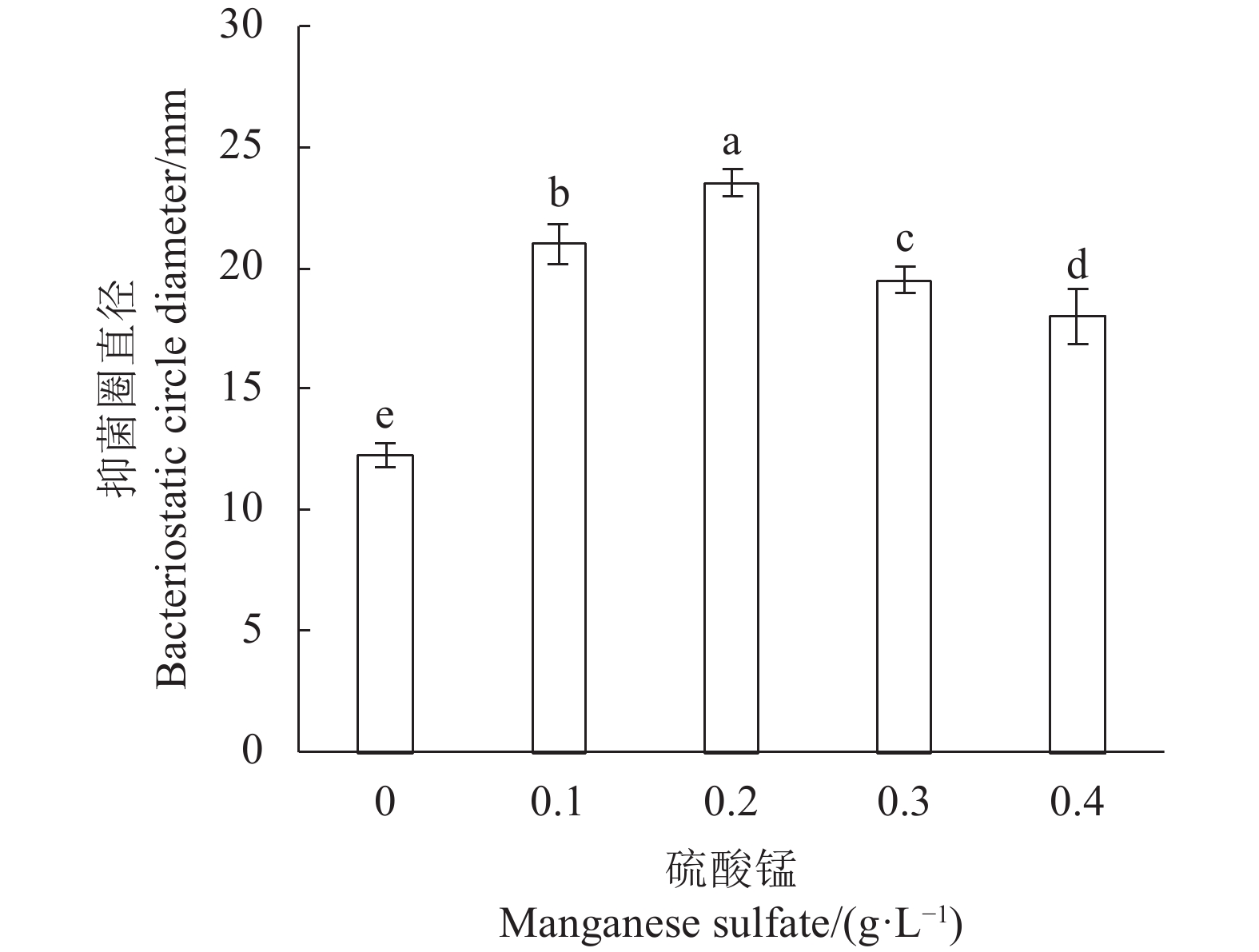

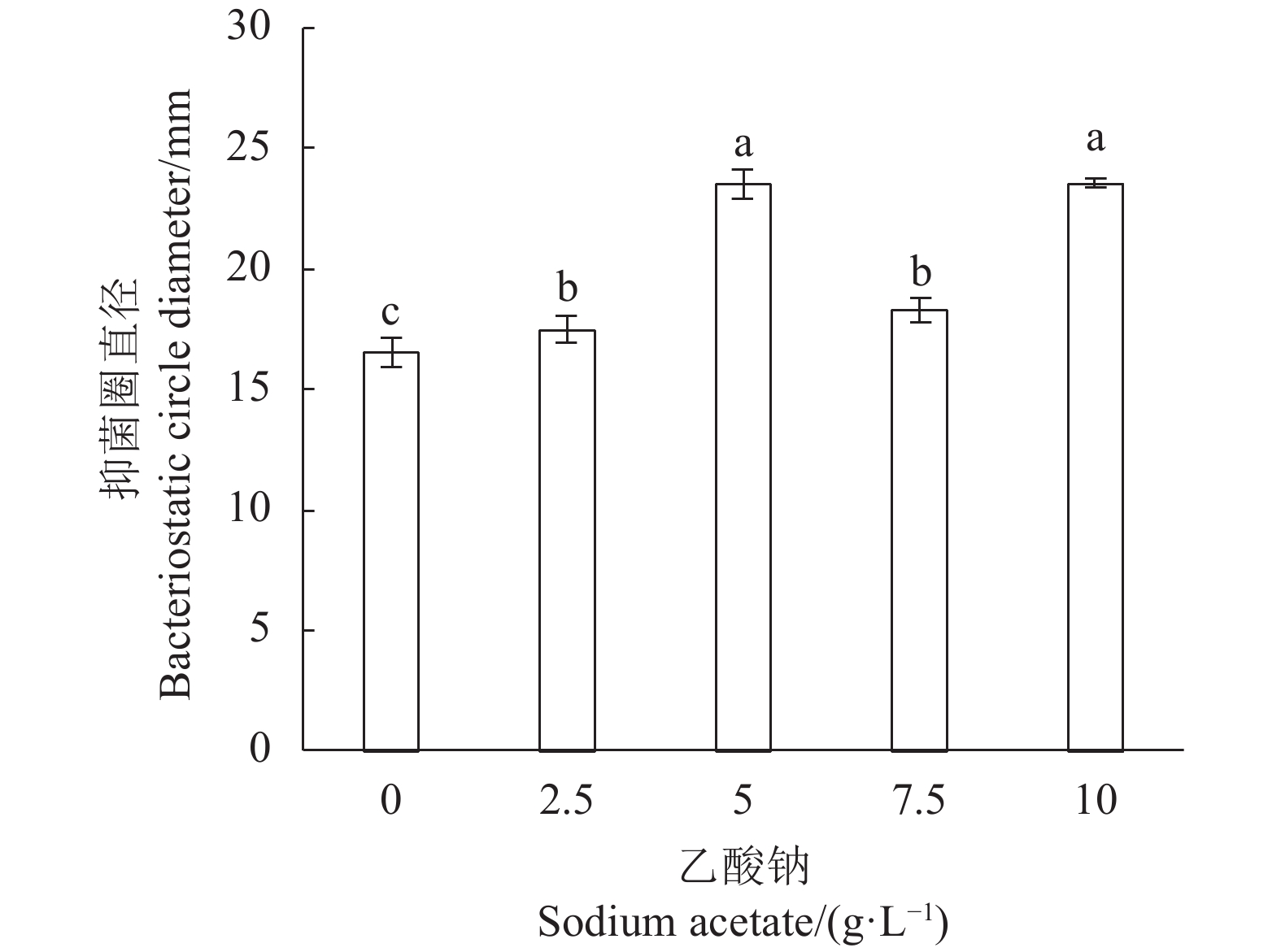

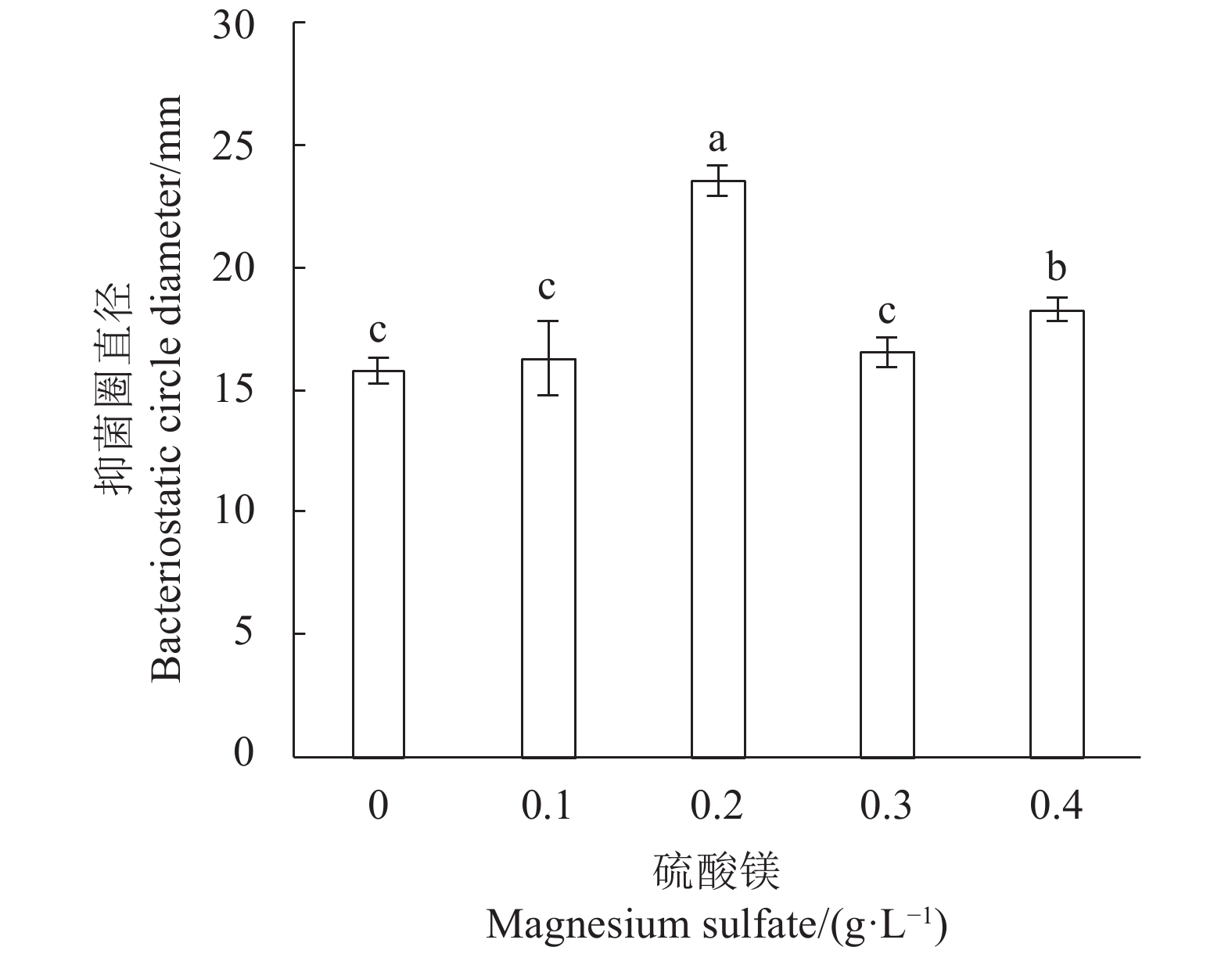

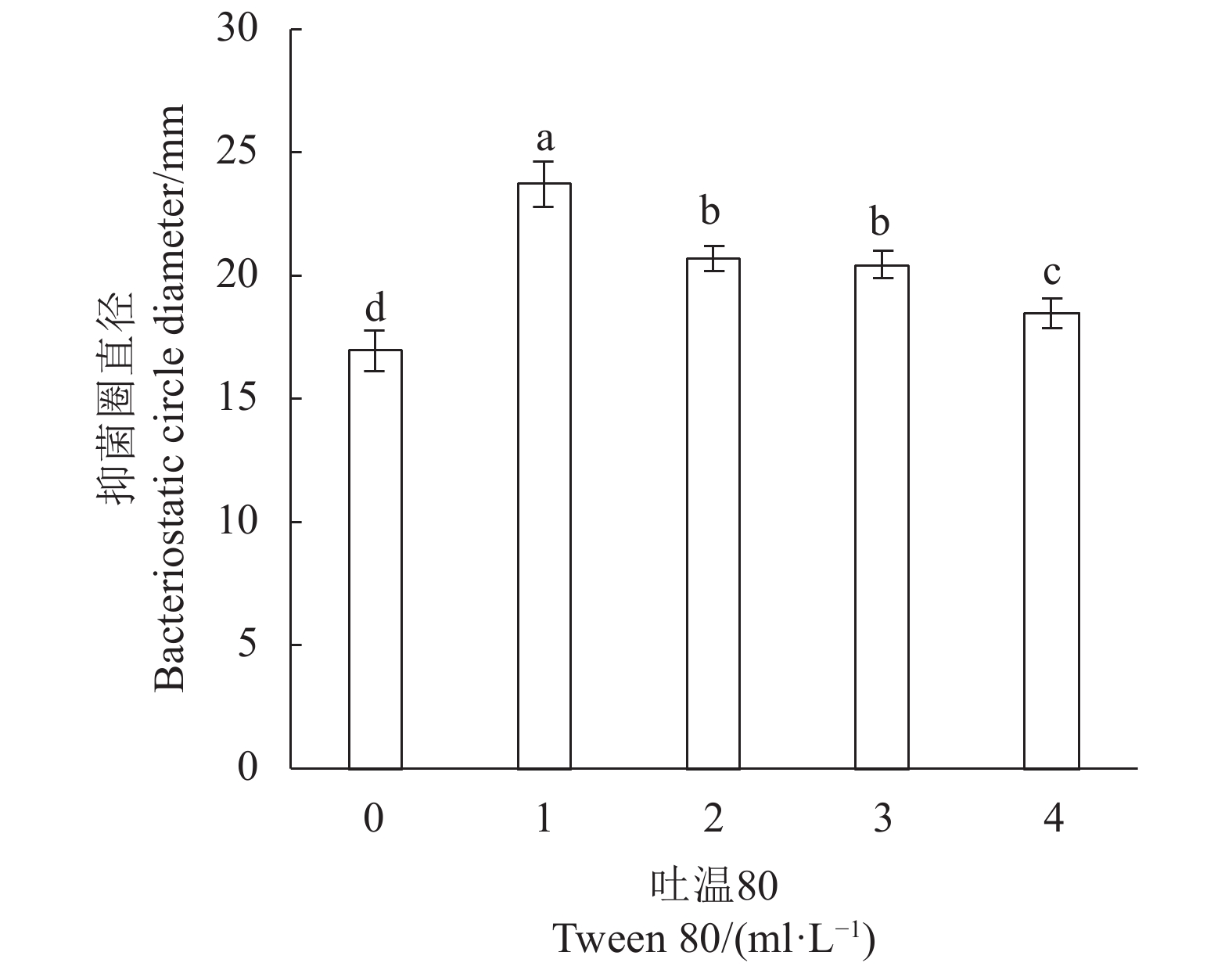

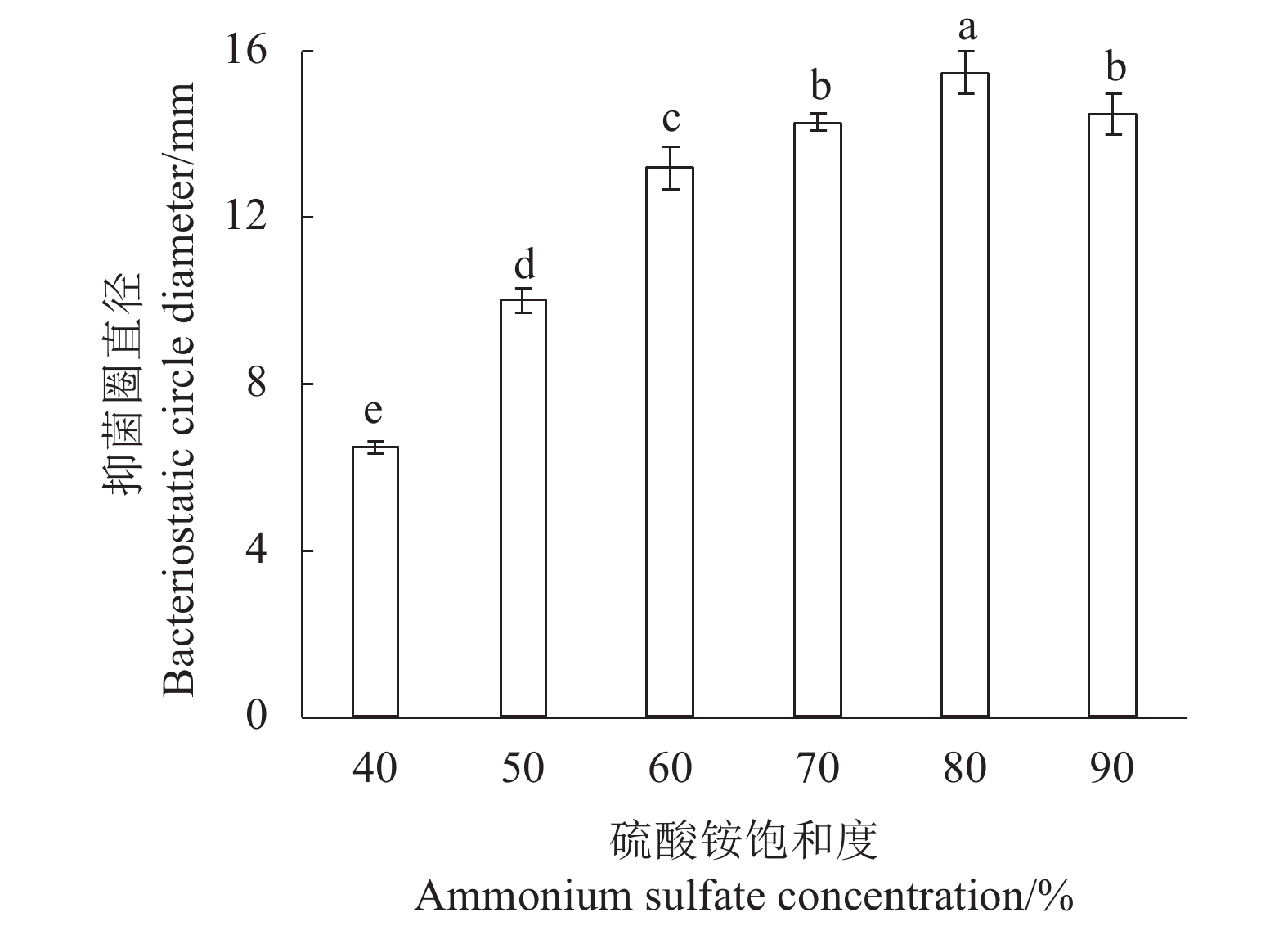

目的 优化植物乳杆菌LV02发酵培养基,研究其抑菌特性,为开发抗菌保鲜类产品提供技术参考。 方法 以大肠杆菌YS为指示菌,抑菌圈直径及生物量OD600为评价指标。在单因素试验的基础上,采用PB试验初步确定各因素的高低水平,接着采用最陡爬坡试验进一步确定步长及方向来接近最大产值,确定CCD试验中心点。最后,采用CCD设计试验,研究各影响因素及其交互作用对植物乳杆菌LV02抑菌性及生物量OD600的影响,确定各影响因素的最佳水平。并通过牛津杯法研究LV02的抑菌特性,来确定应用环境的设定范围。 结果 LV02的优化发酵培养基配方为:葡萄糖34.07 g·L−1、酵母浸粉18.12 g·L−1、磷酸氢二钾2 g·L−1、硫酸锰0.16 g·L−1、乙酸钠5 g·L−1、硫酸镁0.20 g·L−1、柠檬酸铵1 g·L−1、吐温80 1 mL·L−1、胡萝卜汁50 mL·L−1,蒸馏水1 L。以5%接种,37 ℃培养24 h,结果为对大肠杆菌YS的抑菌圈直径比未优化前提高了近26%,OD600提高了12%。通过抑菌特性的分析,确定了粗提植物乳杆菌LV02的细菌素所需硫酸铵饱和度为80%,证明了植物乳杆菌LV02具有热稳定性(100 ℃,120 min)、酸碱稳定性(pH 3.0~7.5)及抑菌性。 结论 采用CCD试验优化植物乳杆菌LV02发酵培养基,可有效提高生物量OD600及对大肠杆菌YS的抑菌性。通过牛津杯法研究LV02的抑菌特性,确定了pH、温度具稳定性的设定范围。 Abstract:Objective Bacteriostatic property of Lactobacillus plantarum LV02 bacteriocin produced on an optimized fermentation medium was determined. Method Based on a single-factor design, the PB and the steepest ascent experiments were conducted to locate the center point of the step length and direction of the influencing factors for a CCD test. Subsequently, effects of different media on the bacteriostatic property and OD600 of the cultured L. plantarum LV02 were evaluated for formulation optimization. The Oxford cup method was employed to determine the bacteriostatic capacity and stability under application conditions of the resulting LV02 bacteriocin produced on the optimized medium. Result The optimized formula for the LV02 fermentation medium in 1 L of water constituted 34.07 g of glucose, 18.12 g of yeast extract, 2 g of dipotassium hydrogen phosphate, 0.16 g of manganese sulfate, 5 g of sodium acetate, 0.20 g of magnesium sulfate, 1 g of ammonium citrate, 1 mL of Tween 80, and 50 mL of carrot juice. On the optimized medium, LV02 grew to yield a 12% increase on OD600 and bacteriocin with a 26% increase on the diameter of inhibition zone against Escherichia coli YS. For the crude LV02 bacteriocin extraction, 80% saturation concentration of ammonium sulfate was used. The antibacterial LV02 bacteriocin was stable under 100 ℃ for 120 m and pH 3.0~7.5. Conclusion L. plantarum LV02 cultured on the optimized fermentation medium was bacteriostatic against E. coli YS. The fermentation produced bacteriocin with desirable stabilities to heat, acid, and slight alkaline condition and was considered promising for the development of an antibacterial agent. -

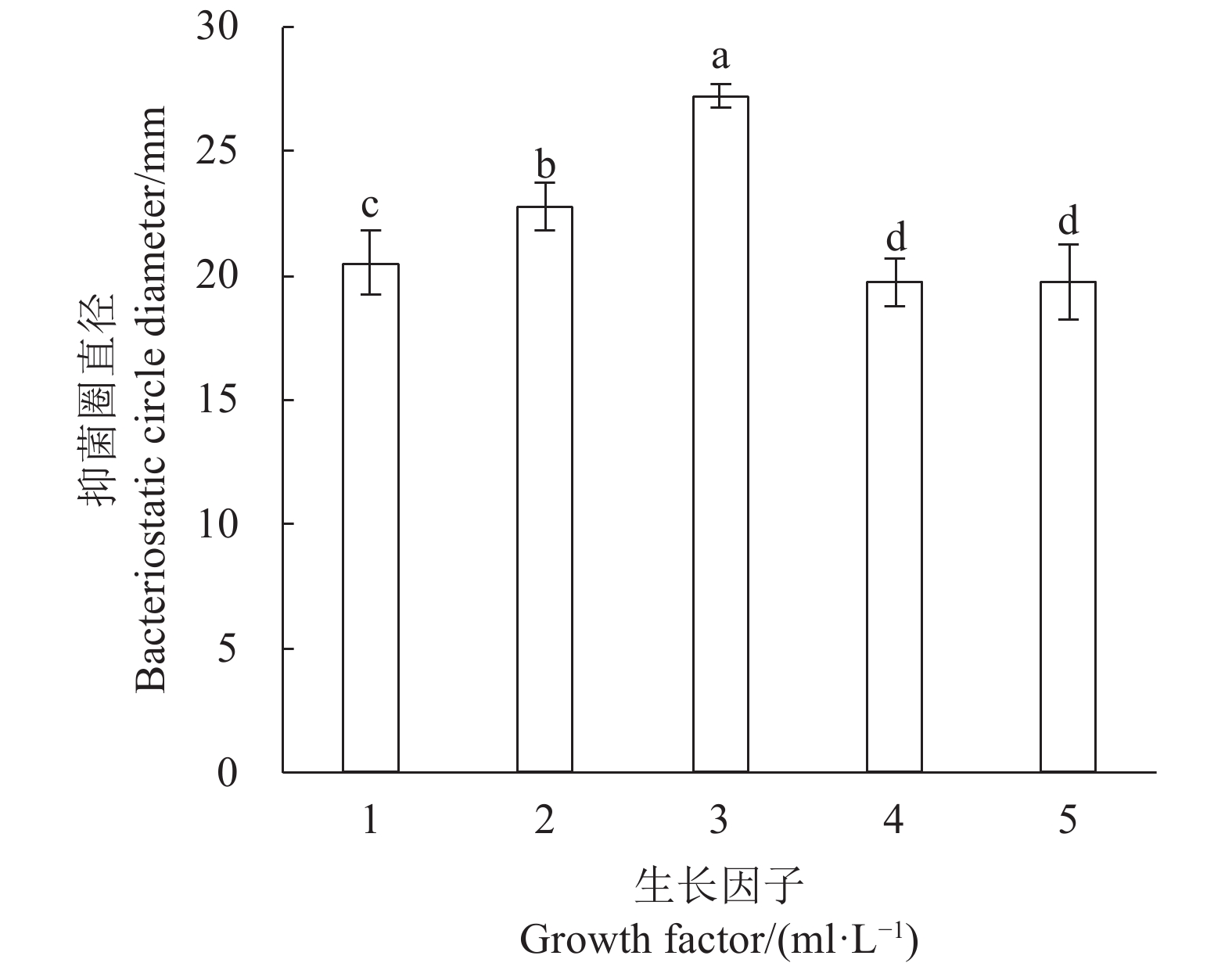

图 10 吐温对LV02的细菌素抗菌效果的影响

注:结合 Duncan 氏法做多重比较,图中标有不同小写字母者表示组间差异显著(P<0.05);相同字母则表示组间差异不显著(P>0.05)。

Figure 10. Effect of Tween-80 in medium on antibacterial activity of LV02 bacteriocin

Note: Combined with Duncan's method for multiple comparisons; those marked with different lowercase letters indicate significant differences between groups (P<0.05); those with same letter indicate no significant differences between groups (P>0.05).

表 1 Plackett-Burman 设计因子水平及编码

Table 1. Factors, levels, and codes of Plackett-Burman experimental design

变量

Variable实际变量

Actual variable单位

Unit低水平

Low level高水平

High Level−1 +1 X1 葡萄糖 Glucose g·L−1 15.00 25.00 X2 酵母浸粉 Yeast extract g·L−1 14.00 24.00 X3 硫酸镁 Magnesium sulfate g·L−1 0.15 0.25 X4 乙酸钠 Sodium acetate g·L−1 3.00 7.00 X5 吐温80 Tween 80 ml·L−1 0.50 1.50 X6 胡萝卜汁 Carrot juice ml·L−1 25.00 75.00 X7 硫酸锰 Manganese sulfate g·L−1 0.15 0.25 表 2 CCD试验各因子水平数

Table 2. Levels for each factor on CCD experiment

变量

Variable实际变量

Actual variable/(g·L−1)水平 Level −1.682 −1 0 +1 +1.682 X1 葡萄糖 Glucose 21.55 27.00 35.00 43.00 48.45 X2 酵母浸粉 Yeast extract 14.64 16.00 18.00 20.00 21.36 X7 硫酸锰 Manganese sulfate 0.06 0.10 0.16 0.22 0.26 表 3 LV02对3种指示菌的抑菌结果

Table 3. Antibacterial results of LV02 against three kinds of ndicator bacteria

指示菌名称

Indicator bacteria保菌编号/

NCBI登录号

Bacteria

number/

NCBI

registration

numberLV02抑菌

圈直径

LV02

inhibition

zone

diameter/

mm大肠杆菌YS Escherichia coli YS MN153456.1 19.41 ± 0.34 猪霍乱沙门氏菌 Salmonella choleraesuis ATCC10708 24.74 ± 0.51 单增李斯特氏菌 Listeria monocytogenes ATCC54001 22.30 ± 0.33 表 4 Plackett-Burman试验结果

Table 4. Results of Plackett-Burman experiment

试验序号

Experiment serial number因子 Factor 抑菌圈直径

Bacteriostatic circle diameter/mmX1 X2 X3 X4 X5 X6 X7 1 +1 +1 −1 +1 +1 +1 −1 23.50 2 −1 +1 +1 −1 +1 +1 +1 18.67 3 +1 −1 +1 +1 −1 +1 +1 23.67 4 −1 +1 −1 +1 +1 −1 +1 18.33 5 −1 −1 +1 −1 +1 +1 −1 20.67 6 −1 −1 −1 +1 −1 +1 +1 20.67 7 +1 −1 −1 −1 +1 −1 +1 21.33 8 +1 +1 −1 −1 −1 +1 −1 21.33 9 +1 +1 +1 −1 −1 −1 +1 20.67 10 −1 +1 +1 +1 −1 −1 −1 21.33 11 +1 −1 +1 +1 +1 −1 −1 23.67 12 −1 −1 −1 −1 −1 −1 −1 21.67 表 5 各因子贡献率及效应值

Table 5. Contribution rates and effect values of individual factors

变量

VariableP值

P value效应值

Effect value贡献率

Contribution rate/%重要性

ImportanceX1 0.0100* 1.07 41.39 1 X2 0.0480* −0.65 15.41 3 X3 0.5433 −0.65 0.86 6 X4 0.0705 0.57 11.73 4 X5 0.3190 −0.26 2.53 5 X6 0.6169 0.13 0.57 7 X7 0.0340* −0.74 19.61 2 注: * :该因子效应显著(P<0.05); * *:该因子效应极显著(P<0.01)。表8、9同。

Note: *: significant at P<0.05; **: extremely significant at P<0.01. The same as table 8、9.表 6 最陡爬坡试验结果

Table 6. Results of steepest ascent experiment

试验组号

Experiment

group

number葡萄糖

Glucose/

(g·L−1)硫酸锰

Manganese

sulfate/

(g·L−1)酵母浸粉

Yeast

extract/

(g·L−1)抑菌圈直径

Bacteriostatic

circle diameter/

mm1 11.00 0.34 24.00 20.87 2 19.00 0.28 22.00 22.00 3 27.00 0.22 20.00 22.47 4 35.00 0.16 18.00 24.50 5 43.00 0.10 16.00 22.42 表 7 中心组合设计及结果

Table 7. CCD design and response values

试验组号

Experiment group number因子

Factor抑菌圈直径

Bacteriostatic circle diameter/mmOD600 葡萄糖X1

Glucose X1硫酸锰X7

Manganese sulfate X7酵母浸粉X2

Yeast extract X2实际值

Actual value预测值

Predictive value实际值

Actual value预测值

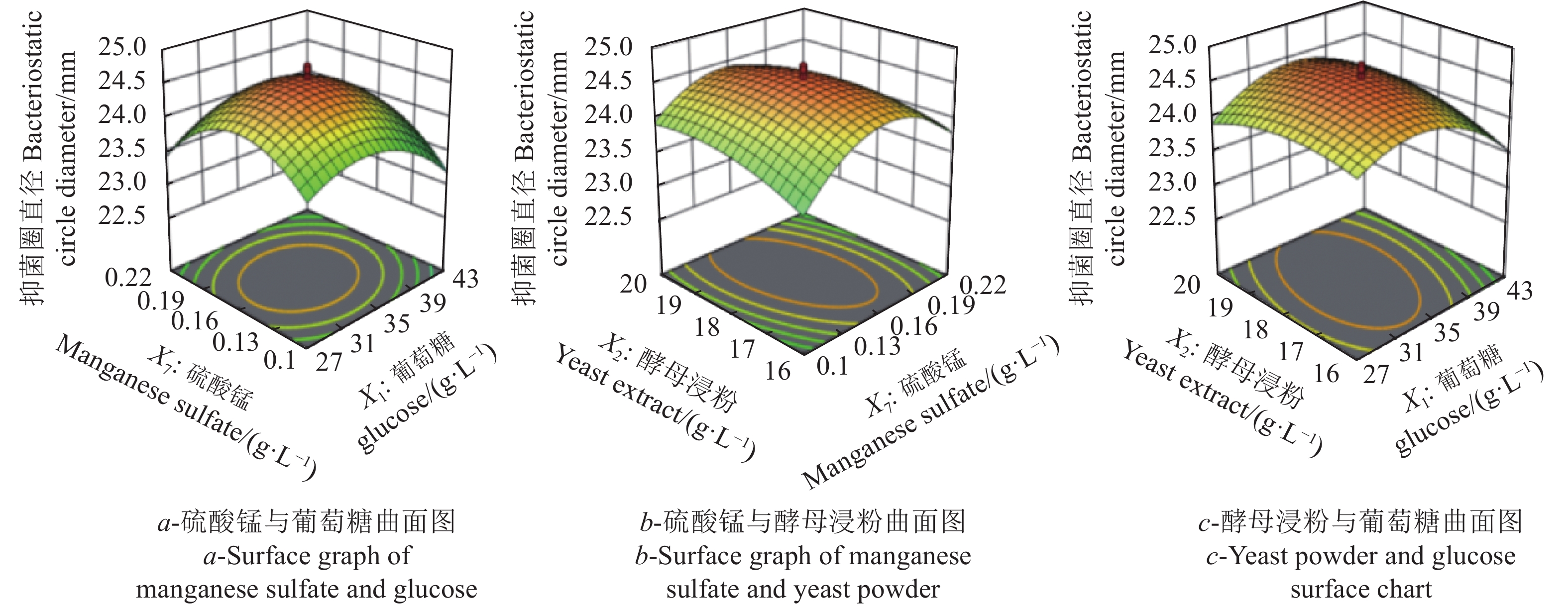

Predictive value1 −1 −1 −1 23.55 23.44 2.680 2.690 2 +1 −1 −1 22.80 22.65 2.598 2.560 3 −1 +1 −1 23.43 23.48 2.690 2.680 4 +1 +1 −1 23.40 23.13 2.620 2.580 5 −1 −1 +1 23.40 23.53 2.620 2.640 6 +1 −1 +1 23.52 23.33 2.682 2.660 7 −1 +1 +1 23.00 23.01 2.600 2.610 8 +1 +1 +1 23.33 23.25 2.700 2.660 9 −1.682 0 0 23.53 23.38 2.684 2.650 10 +1.682 0 0 22.58 22.92 2.510 2.580 11 0 −1.682 0 22.67 22.76 2.580 2.590 12 0 +1.682 0 22.62 22.73 2.550 2.580 13 0 0 −1.682 23.73 23.92 2.700 2.730 14 0 0 +1.682 24.10 24.11 2.750 2.760 15 0 0 0 24.63 24.56 2.852 2.880 16 0 0 0 24.72 24.56 2.895 2.880 17 0 0 0 24.75 24.56 2.903 2.880 18 0 0 0 24.00 24.56 2.850 2.860 19 0 0 0 24.60 24.56 2.860 2.850 20 0 0 0 24.70 24.56 2.900 2.900 表 8 以抑菌圈直径为响应值的回归方程方差分析

Table 8. Analysis of variance for regression model based on bacteriostatic zone diameter as response value

方差来源

Source of

variance平方和

Sum of

square自由度

Degree of

freedomF值

F valueP值

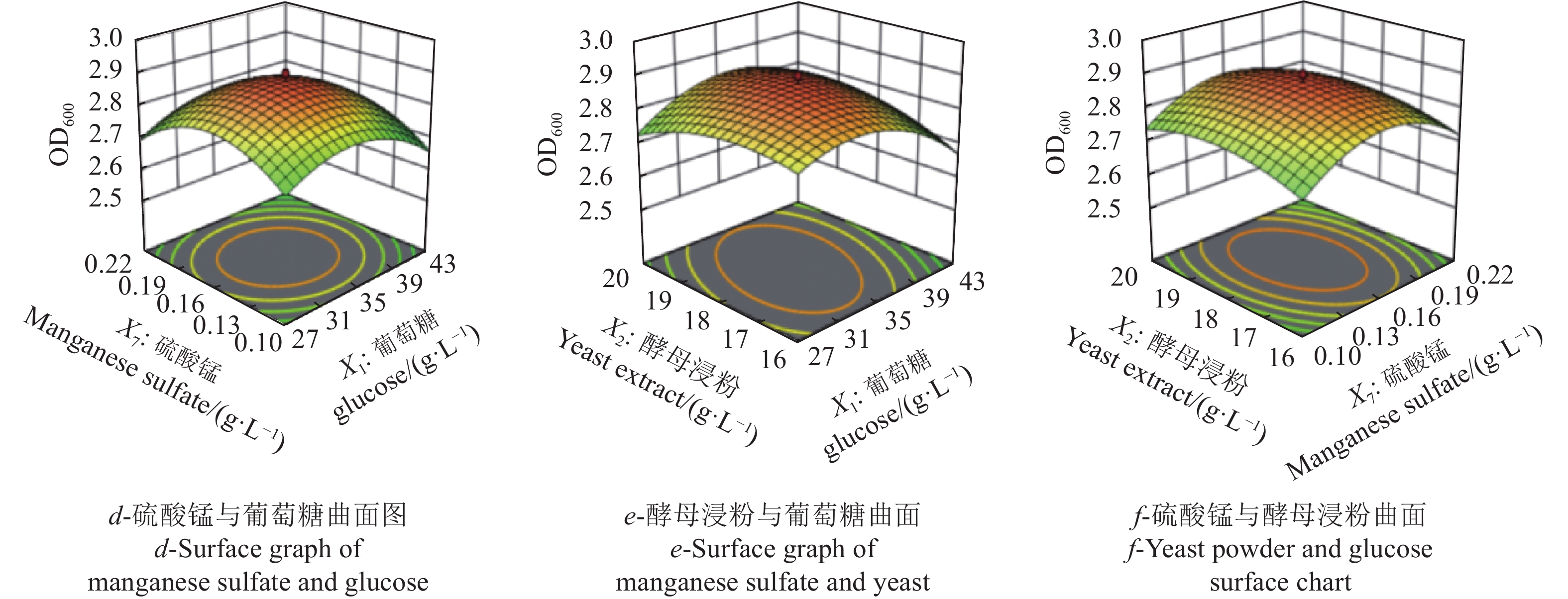

P value模型 Model 9.5300 9 13.9700 0.000 1** X1 0.2600 1 3.4100 0.094 7 X7 1.520×10−3 1 0.0200 0.890 2 X2 0.0400 1 0.5300 0.482 4 X1*X7 0.0970 1 1.2800 0.284 8 X1*X2 0.0170 1 2.3000 0.160 7 X7*X2 0.1600 11 2.0740 0.180 9 X12 3.5700 11 7.0600 <0.000 1** X72 5.9500 1 78.4800 <0.000 1** X22 0.5400 1 7.1200 0.023 6* 残差 Residual 0.7600 10 失拟项 Missing item 0.3600 5 0.8900 0.549 4 表 9 以OD600为响应值的回归方程方差分析

Table 9. Analysis of variance for regression model based on OD600 as response value

方差来源

Source of

variance平方和

Sum of

square自由度

Degree of

freedomF值

F valueP值

P value模型 Model 0.2800 9 17.6700 <0.000 1** X1 12.9020 1 3.3100 0.098 8 X7 3.065×10−5 1 0.0170 0.897 8 X2 7.046×10−4 1 0.4000 0.541 8 X1*X7 3.125×10−4 1 0.1800 0.682 9 X1*X2 0.0120 1 6.9800 0.024 7* X7*X2 1.445×10−4 1 0.0820 0.780 7 X12 0.1200 1 68.5700 <0.000 1** X72 0.1500 1 86.5400 <0.000 1** X22 0.0310 1 17.5800 0.0019** 残差 Residual 0.0180 10 失拟项 Missing item 0.0140 5 4.3200 0.067 0 表 10 LV02发酵培养基验证试验结果

Table 10. Verification of LV02 fermentation medium

试验组别

Test Group葡萄糖

glucose/

(g·L−1)酵母浸粉

Yeast extract/(g·L−1)牛肉膏+蛋白胨+

酵母粉

Beef extract+

peptone+

yeast powder/

(g·L−1)硫酸锰

Manganese sulfate/

(g·L−1)胡萝卜汁

Carrot juice/

(mL·L−1)抑菌圈直径

Bacteriostaticcircle

diameter/mmOD600 对照组 Control group 20.00 — 19.00 0.20 — 19.36 ± 0.27 2.435 ± 0.030 预测组 Forecast Group 34.07 18.12 — 0.16 50.00 24.58 2.877 实验组 Test group 34.07 18.12 — 0.16 50.00 24.50 ± 0.31 2.877 ± 0.230 -

[1] SON S H, JEON H L, JEON E B, et al. Potential probiotic Lactobacillus plantarum Ln4 from kimchi: Evaluation of β-galactosidase and antioxidant activities [J]. LWT - Food Science and Technology, 2017, 85: 181−186. doi: 10.1016/j.lwt.2017.07.018 [2] 杨永亮. 泡菜中植物乳杆菌的分离鉴定及其应用[D]. 广州: 华南理工大学, 2013.YANG Y L. Isolation and identification of the Lactobacillus Plantarum strain from pickles and its application[D]. Guangzhou: South China University of Technology, 2013.(in Chinese) [3] 金银卡编辑部. 乳酸菌素在饲料中应用研究 [J]. 广东饲料, 2016, 25(12):32−34.Editorial Department of Gold and Silver Cards. Study on the application of lactobacteriocin in feed [J]. Guangdong Feed, 2016, 25(12): 32−34.(in Chinese) [4] KUMAR V, SHEORAN P, GUPTA A, et al. Antibacterial property of bacteriocin produced by Lactobacillus plantarum LD4 isolated from a fermented food [J]. Annals of Microbiology, 2016, 66(4): 1431−1440. doi: 10.1007/s13213-016-1230-6 [5] 刘彩琴, 陆胤, 王石磊,等. 黄酒米浆水中抗菌乳酸菌的筛选及特性分析[J]. 食品工业科技, 2020(9):115 − 118 .LIU C Q, LU Y, WANG S L, et al. Screening and characteristics analysis of antibacterial lactic acid bacteria from rice pulp of huangjiu[J]. Food Industry Science and Technology, 2019: 115 − 118.(in Chinese) [6] 姜旭德, 张春华. 乳酸菌素及其乳酸链球菌素在食品中的应用 [J]. 中国乳业, 2017(2):60−62.JIANG X D, ZHANG C H. The application of lactobacteriocin and nisin in food processing [J]. China Dairy, 2017(2): 60−62.(in Chinese) [7] 张敏. pH对植物乳杆菌KDFR27生长的影响[D]. 哈尔滨: 东北农业大学, 2016.ZHANG M. Effect of pH on the growth of Lactobacillus plantarum KDFR27[D]. Harbin: Northeast Agricultural University, 2016.(in Chinese) [8] 刘伦伦, 刘焱, 瞿朝霞, 等. 植物乳杆菌发酵盐渍辣椒汁培养基的优化 [J]. 中国酿造, 2014, 33(2):32−36. doi: 10.3969/j.issn.0254-5071.2014.02.008LIU L L, LIU Y, QU Z X, et al. Optimization of pepper juice medium for Lactobacillus plantarum [J]. China Brewing, 2014, 33(2): 32−36.(in Chinese) doi: 10.3969/j.issn.0254-5071.2014.02.008 [9] 王瑶, 李琪, 李平兰. 植物乳杆菌LPL-1产细菌素发酵培养基优化 [J]. 农业机械学报, 2018, 49(9):311−317. doi: 10.6041/j.issn.1000-1298.2018.09.036WANG Y, LI Q, LI P L. Optimization of fermentation medium of Lactobacillus plantarum LPL-1 for plantaricin LPL-1 production by response surface methodology [J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(9): 311−317.(in Chinese) doi: 10.6041/j.issn.1000-1298.2018.09.036 [10] 王瑶, 李琪, 李平兰. 响应面法优化植物乳杆菌LPL-1产细菌素发酵条件及细菌素理化性质分析 [J]. 食品科学, 2018, 39(22):101−109. doi: 10.7506/spkx1002-6630-201822016WANG Y, LI Q, LI P L. Optimization of fermentation conditions for plantaricin production by Lactobacillus plantarum LPL-1 by response surface methodology and its physicochemical properties [J]. Food Science, 2018, 39(22): 101−109.(in Chinese) doi: 10.7506/spkx1002-6630-201822016 [11] 徐珑倩, 胡凯弟, 张艾青, 等. 植物乳杆菌P158产细菌素培养基及培养条件的优化 [J]. 食品科学, 2017, 38(22):109−116. doi: 10.7506/spkx1002-6630-201722017XU L Q, HU K D, ZHANG A Q, et al. Optimization of medium and culture conditions for bacteriocin production by Lactobacillus plantarum P158 [J]. Food Science, 2017, 38(22): 109−116.(in Chinese) doi: 10.7506/spkx1002-6630-201722017 [12] ZHAO S M, HAN J Z, BIE X M, et al. Purification and characterization of plantaricin JLA-9: A novel bacteriocin against Bacillus spp. produced by Lactobacillus plantarum JLA-9 from Suan-tsai, a traditional Chinese fermented cabbage [J]. Journal of Agricultural and Food Chemistry, 2016, 64(13): 2754−2764. doi: 10.1021/acs.jafc.5b05717 [13] 许女, 史改玲, 张浩, 等. 植物乳杆菌KF1对奶牛乳房炎金黄色葡萄球菌的抑茵机制 [J]. 中国食品学报, 2016, 16(10):19−27.XU N, SHI G L, ZHANG H, et al. Antibacterial mechanism of Lactobacillus plantarum KF1 on Staphylococcus aureus isolated from subclinical mastitis milk [J]. Journal of Chinese Institute of Food Science and Technology, 2016, 16(10): 19−27.(in Chinese) [14] YOO H, RHEEM I, RHEEM S, et al. Optimizing medium components for the maximum growth of Lactobacillus plantarum JNU 2116 using response surface methodology [J]. Korean Journal for Food Science of Animal Resources, 2018, 38(2): 240−250. [15] 高秀芝, 康建依, 易欣欣, 等. 一种发酵蔬菜的混合益生菌、发酵蔬菜及其制备方法: 中国, 110106112A[P]. 2019−08−09. [16] 沈菲儿. 乳酸菌发酵对莲藕泡菜质构和风味影响的研究[D]. 扬州: 扬州大学, 2016.SHEN F E. Study on the effect of lactic acid bacteria fermentation on the texture and flavor of lotus root kimchi[D]. Yangzhou: Yangzhou University, 2016(in Chinese) [17] 张子豪. 高效抑制大肠埃希氏菌的芽孢杆菌筛选及其抑菌特性研究[D]. 北京: 北京农学院, 2018.ZHANG Z H. Optimization of fermentation culture medium and conditions of Bacillus with high antibacterial activity against Escherichia coli[D]. Beijing: Beijing University of Agriculture, 2018.(in Chinese) [18] 赵玉鉴. 益生性植物乳杆菌 C88 直投式发酵剂的制备及其应用[D]. 长春: 吉林农业大学, 2014.ZHAO Y J. Preparation and application of probiotic Lactobacillus plantarum C88 direct vat set culture[D]. Changchun: Jilin Agricultural University, 2014.(in Chinese) [19] 汤夏安, 刘彩莲, 邓业成, 等. 广西地不容内生真菌DBR-9产橘霉素的发酵条件优化 [J]. 河南农业科学, 2019, 48(7):81−87.TANG X A, LIU C L, DENG Y C, et al. Optimization of Fermentation Conditions for the Production of Citrinin from Endophytic Fungus DBR-9 of Stephania kwangsiensis [J]. Journal of Henan Agricultural Sciences, 2019, 48(7): 81−87.(in Chinese) [20] 杨慧娟. 具有抑制甜瓜枯萎病菌的植物乳杆菌筛选及其抑菌特性研究[D]. 呼和浩特: 内蒙古农业大学, 2014.YANG H J. Selection of fusarium oxysporum Inhibitory L. plantarum strains and characterization of their antifungal activity[D]. Hohhot: Inner Mongolia Agricultural University, 2014. (in Chinese) [21] 姜晶, 敖日格乐, 王纯洁, 等. 酸马奶提取植物乳杆菌DSM20174细菌素的理化特性研究 [J]. 中国畜牧兽医, 2016, 43(2):444−449.JIANG J, AORIGELE, WANG C J, et al. Study on physicochemical properties of Lactobacillus plantarum DSM20174 bacteriocin from koumiss [J]. China Animal Husbandry & Veterinary Medicine, 2016, 43(2): 444−449.(in Chinese) [22] 唐坚. 生菜的冰温保鲜及微生物预测模型的初步建立[D]. 上海: 上海师范大学, 2015.TANG J. Freezing-pointstorage of lettuce and thepreliminary establishment of predictionmodel of microorganisms[D]. Shanghai: Shanghai Normal University, 2015.(in Chinese) [23] KORDEL M, SAHL H G. Susceptibility of bacterial, eukaryotic and artificial membranes to the disruptive action of the cationic peptides Pep 5 and nisin [J]. FEMS Microbiology Letters, 1986, 34(2): 139−144. doi: 10.1111/j.1574-6968.1986.tb01393.x [24] 章检明. 植物乳杆菌 B23 合成细菌素发酵条件优化及诱导调控研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.ZHANG J M. Optimization of fermentationconditions and research of inductionregulation for bacteriocin productionby Lactobacillus plantarum B 23[D]. Harbin: Harbin Institute of Technology, 2015.(in Chinese) [25] 王莉. 食品营养学[M]. 第三版. 北京: 化学工业出版社, 2018: 93. [26] 王帅. 植物乳杆菌培养及冻干技术研究[D]. 西安: 陕西科技大学, 2016.WANG S. Study on cultivation and cryoprotectant of Lactobacillus plantarum[D]. Xian: Shaanxi Universityof Science and Technology, 2016.(in Chinese) [27] 施铜铃, 卢烨, 梁金钟. 嗜酸乳杆菌HUC-La-0812菌株高密度生长培养基的优化 [J]. 乳业科学与技术, 2009, 32(6):271−274. doi: 10.3969/j.issn.1671-5187.2009.06.007SHI T L, LU Y, LIANG J Z. Optimization of high-density growth medium of Lactobacillus acidophilus strain HUC-La-0812 [J]. Journal of Dairy Science and Technology, 2009, 32(6): 271−274.(in Chinese) doi: 10.3969/j.issn.1671-5187.2009.06.007 [28] 赵静. 直投式微生物菌剂及发芽谷物发酵饮品的研究[D]. 哈尔滨: 哈尔滨商业大学, 2015.ZHAO J. Researched on direct vat set(dvs) microbial starter and sprouting grains fermented beverages[D]. Harbin: Harbin University of Commerce, 2015.(in Chinese) [29] 杨杰, 谷新晰, 李晨, 等. 响应面法优化植物乳杆菌绿豆乳增殖培养基 [J]. 中国食品学报, 2015, 15(12):83−90.YANG J, GU X X, LI C, et al. Optimization of multiplying culture of mungbean milk of Lactobacillus plantarum by response surface method [J]. Journal of Chinese Institute of Food Science and Technology, 2015, 15(12): 83−90.(in Chinese) [30] 刘正奇. 植物乳杆菌WLPL04的胞外多糖结构与益生功能研究及其发酵工艺优化[D]. 南昌: 南昌大学, 2018.LIU Z Q. Research on structure and probiotic function of exopolysaccharide from Lactobacillus plantarum WLPL04 and optimization of its fermentation processes[D]. Nanchang: Nanchang University, 2018. (in Chinese) -

下载:

下载: