Gluten Network of Dough Affected by Addition of γ-Polyglutamic Acid

-

摘要:

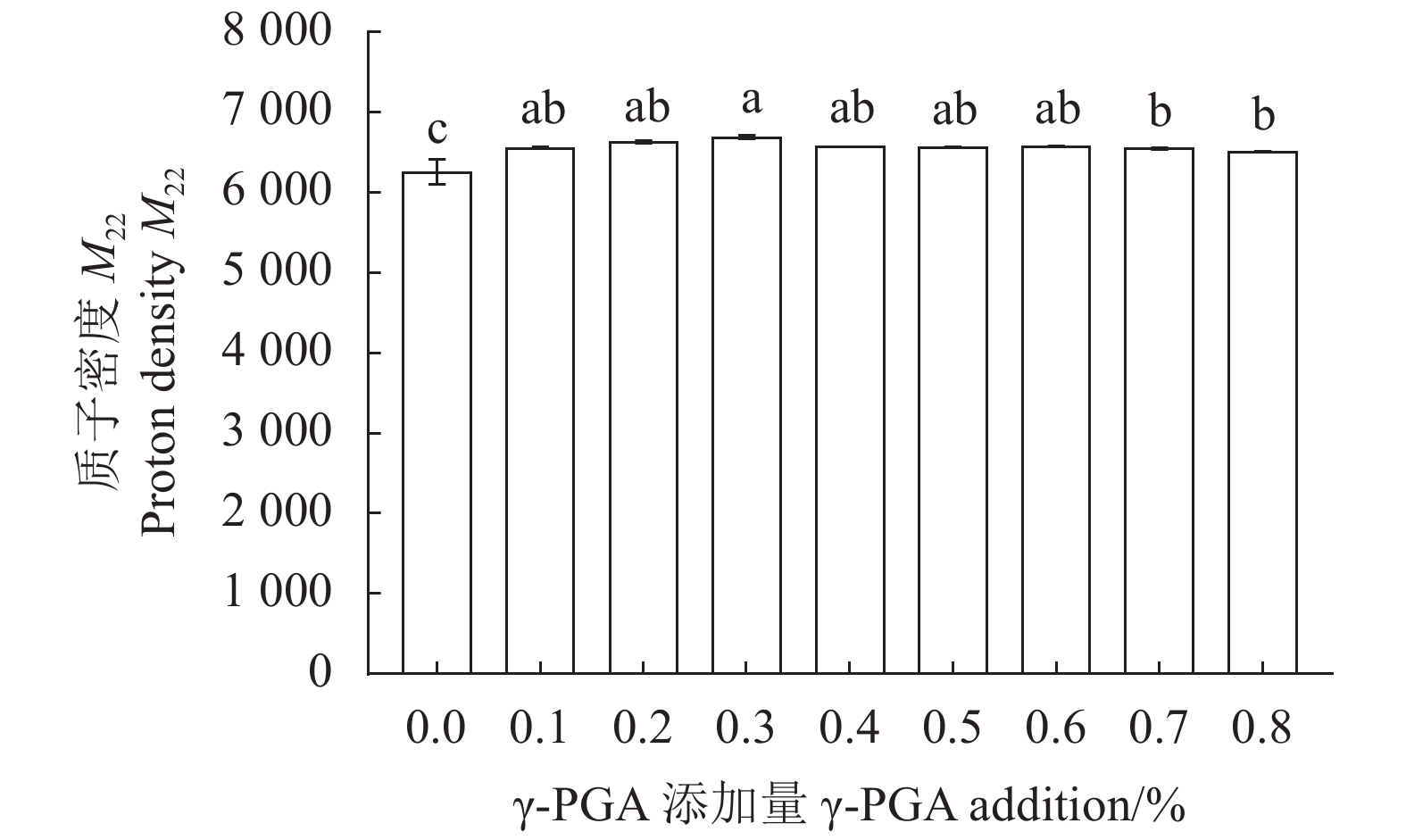

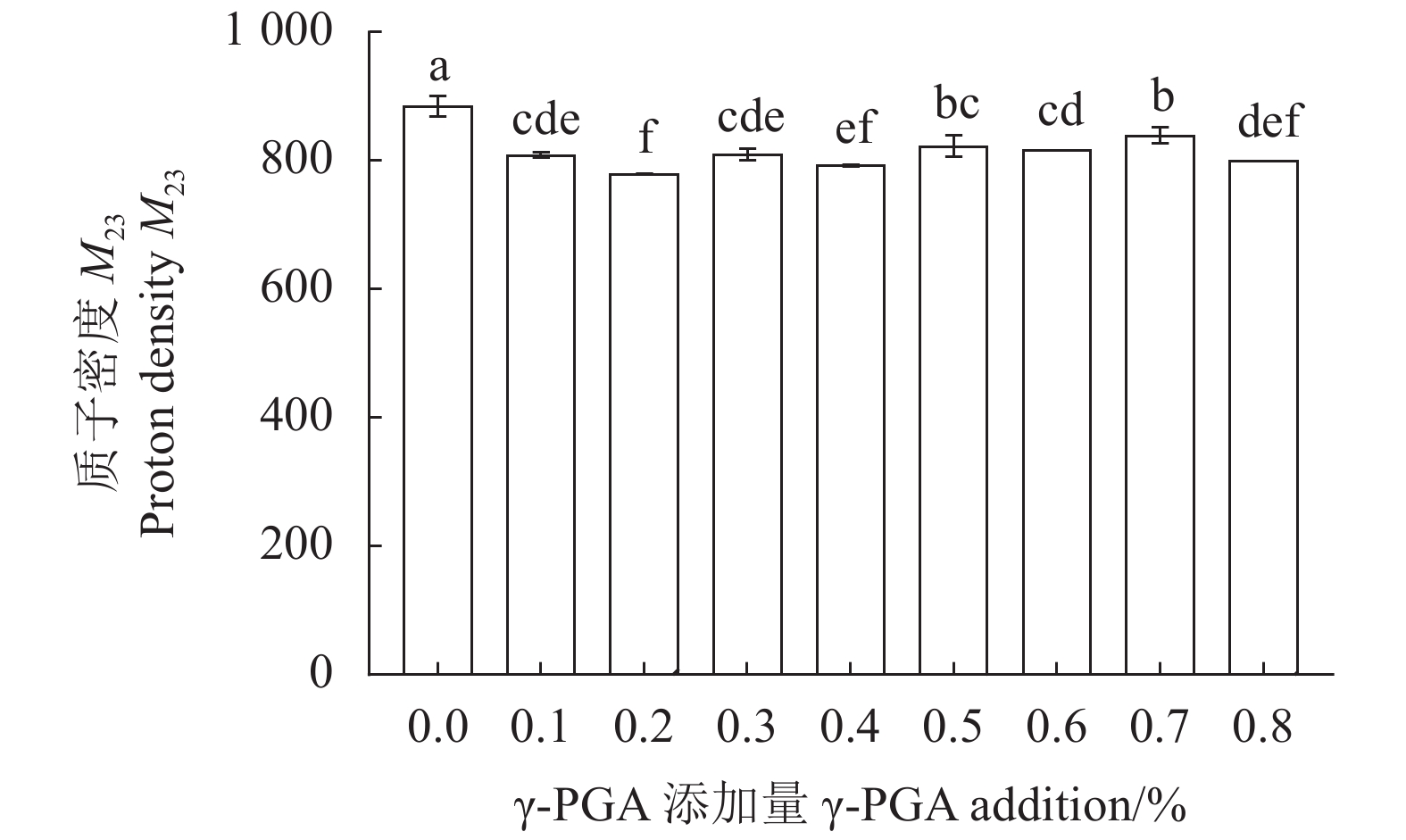

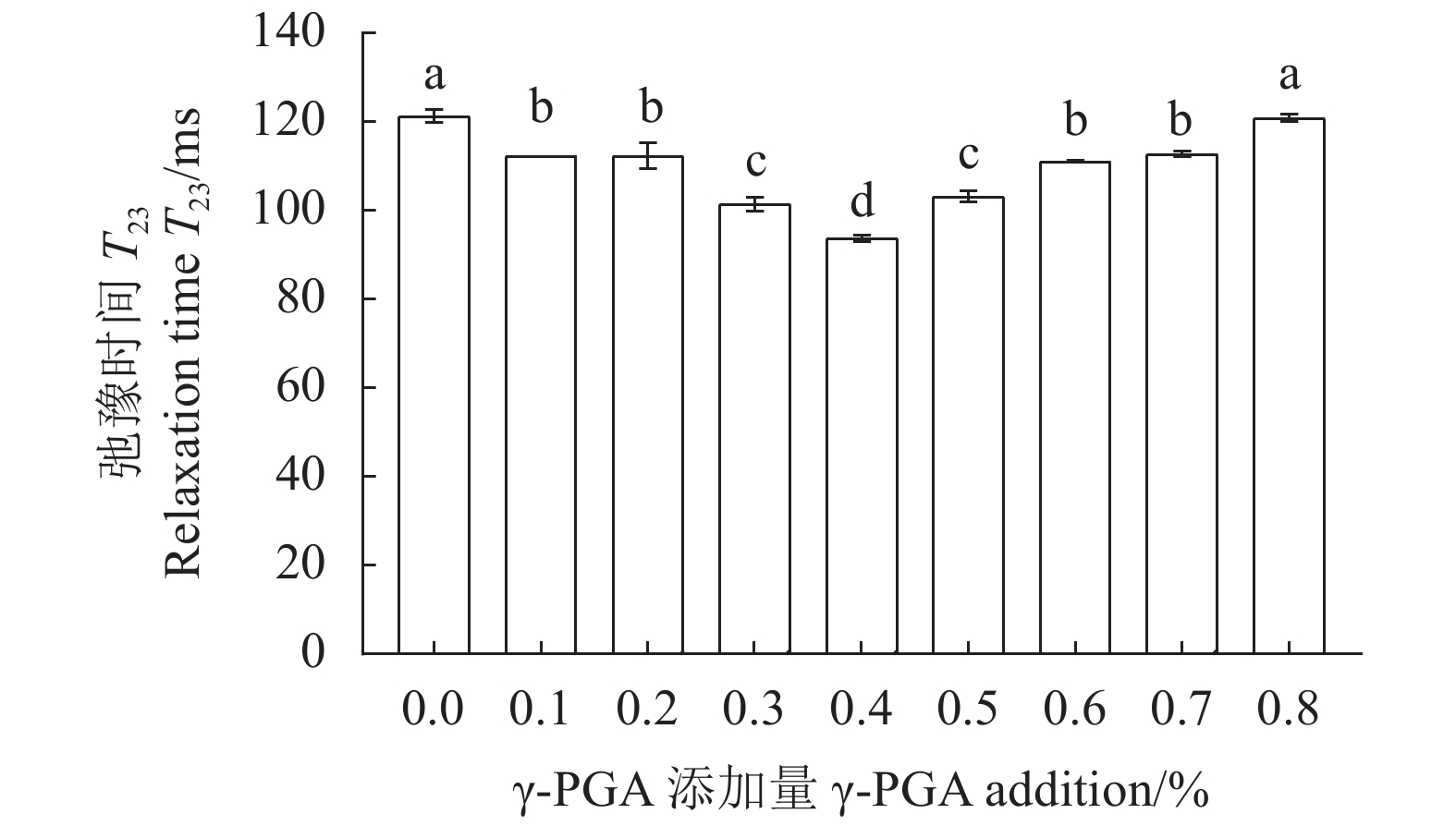

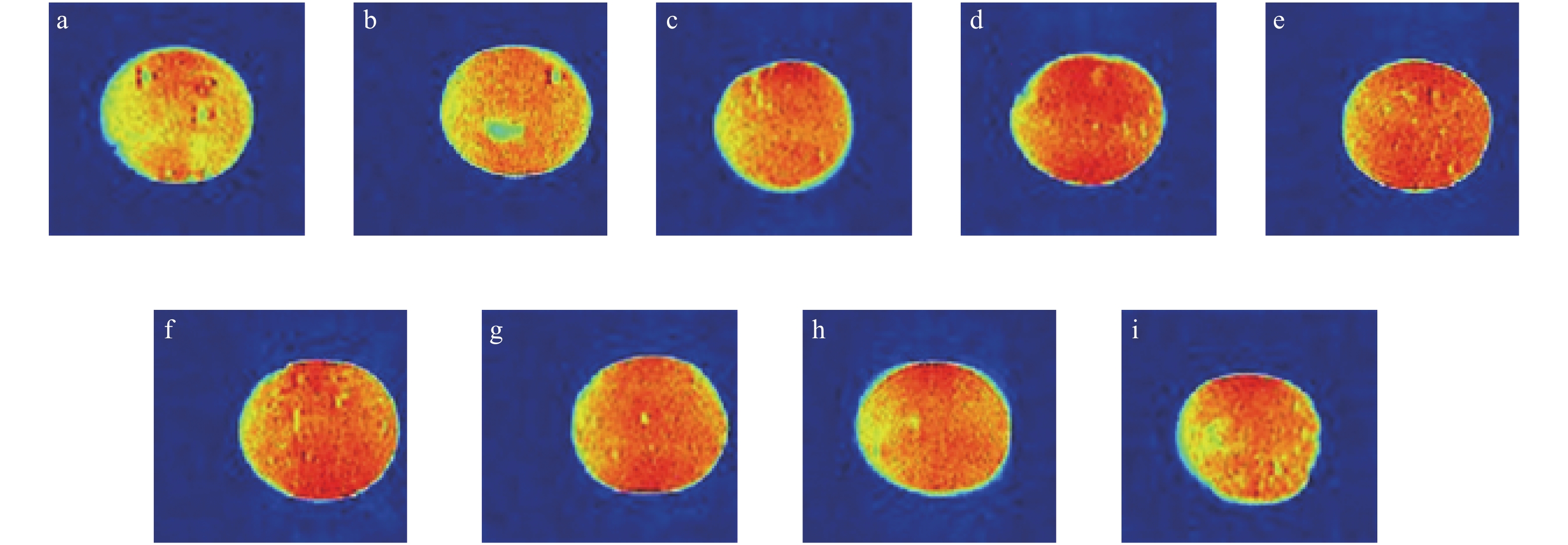

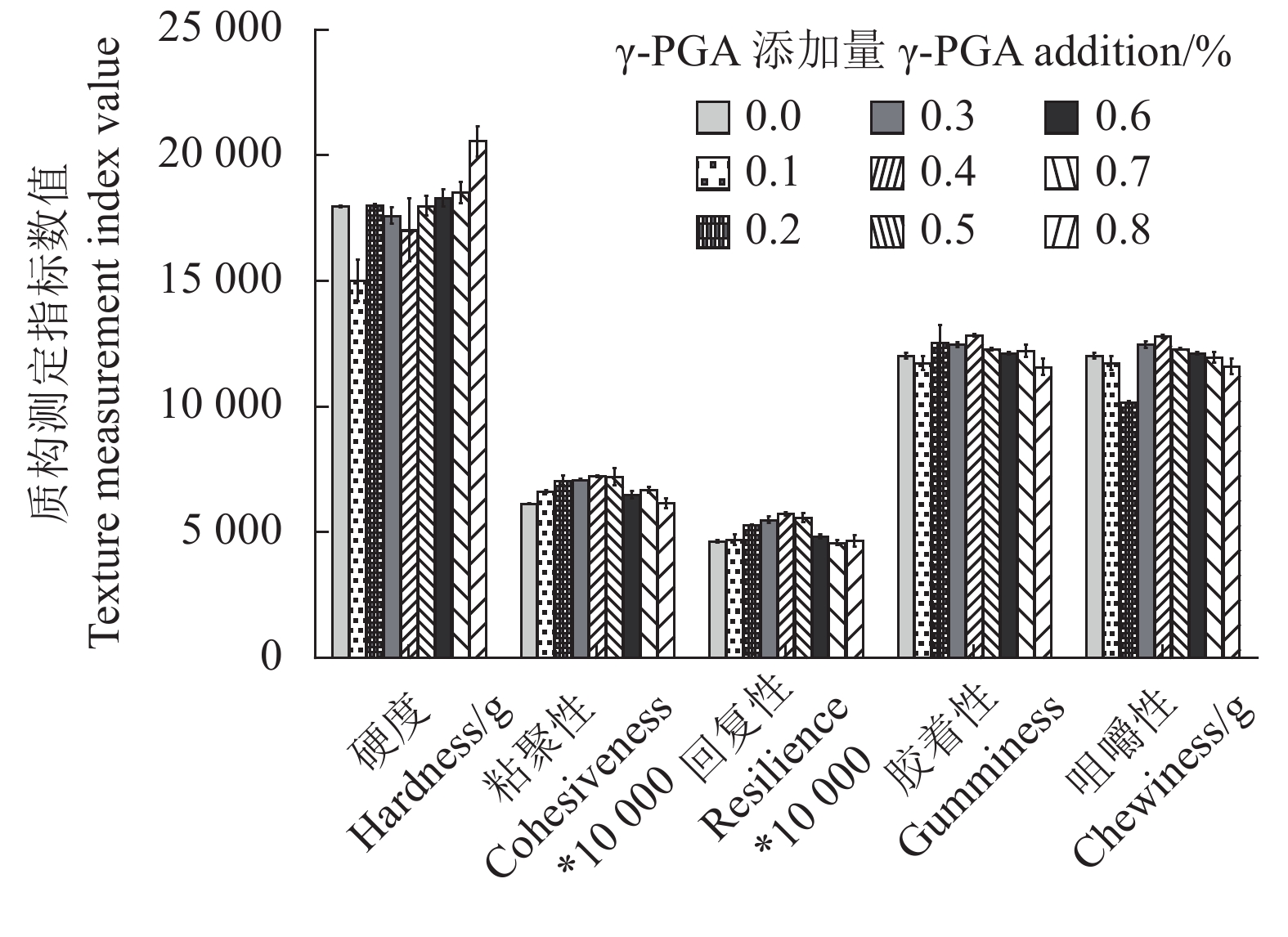

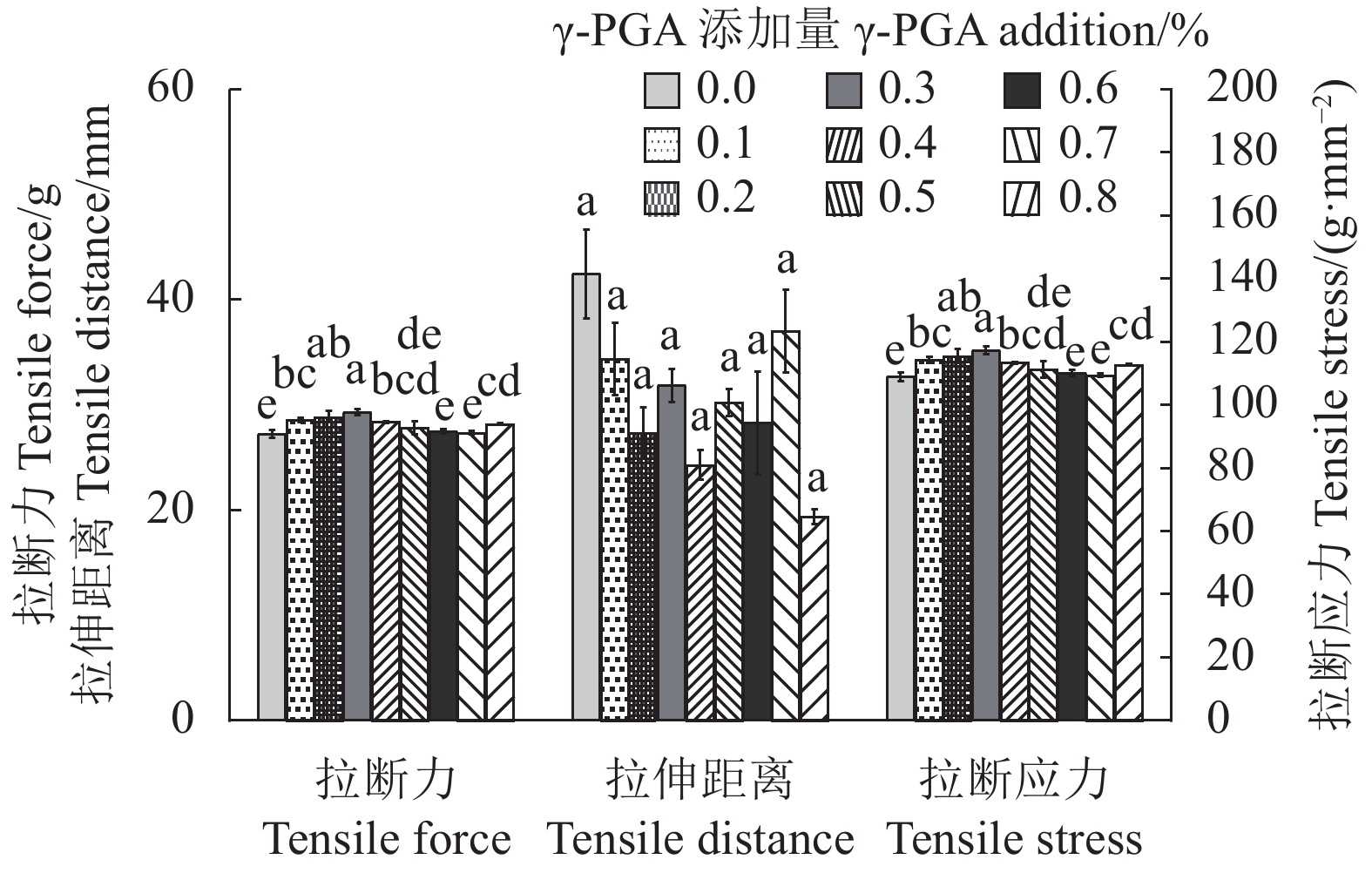

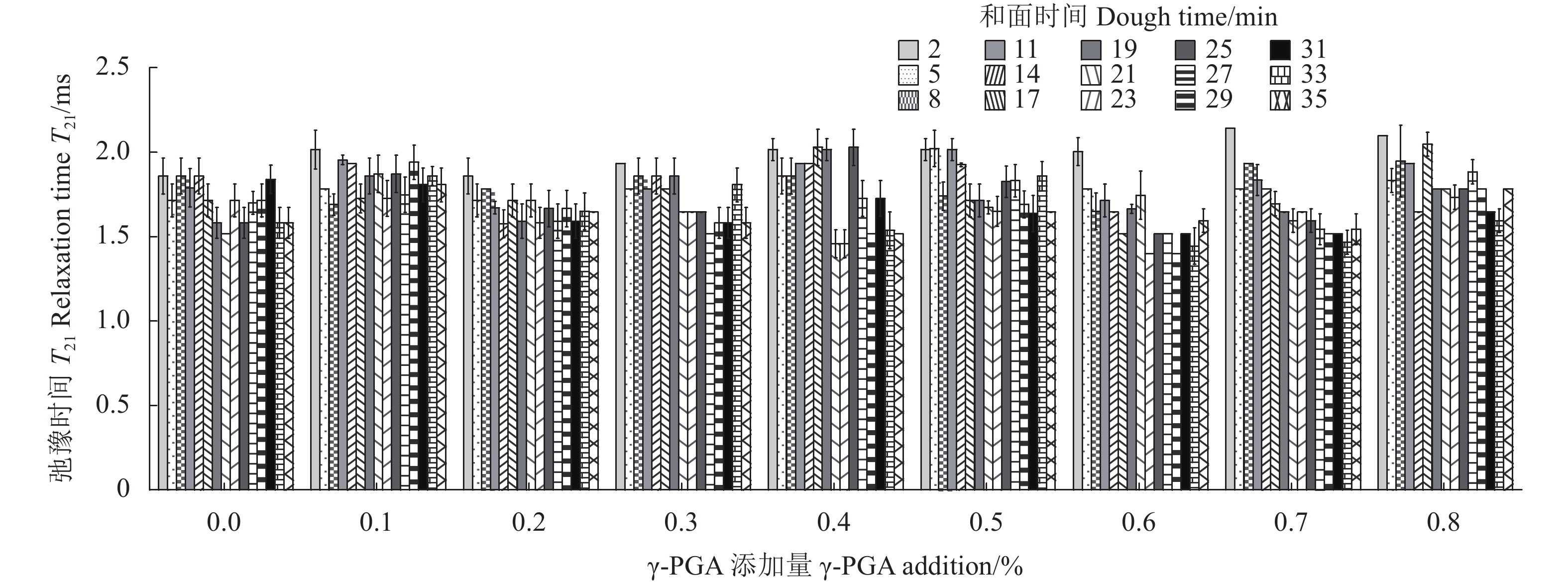

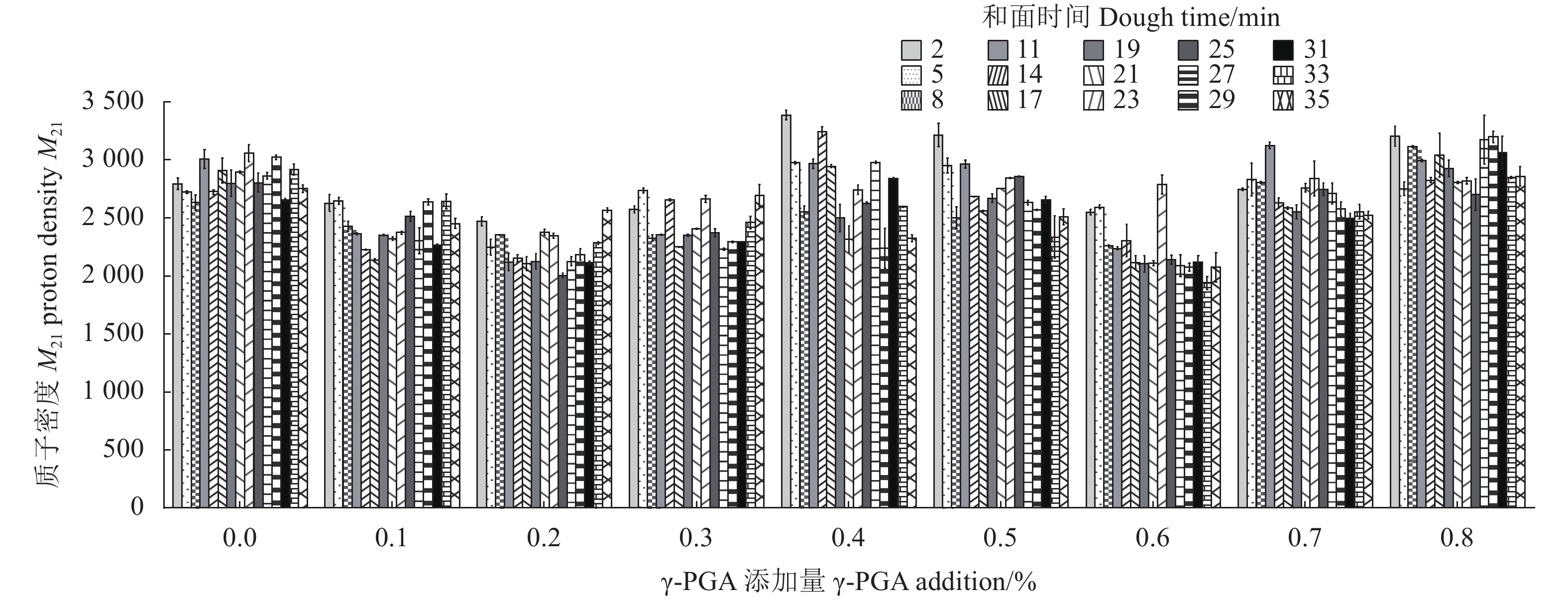

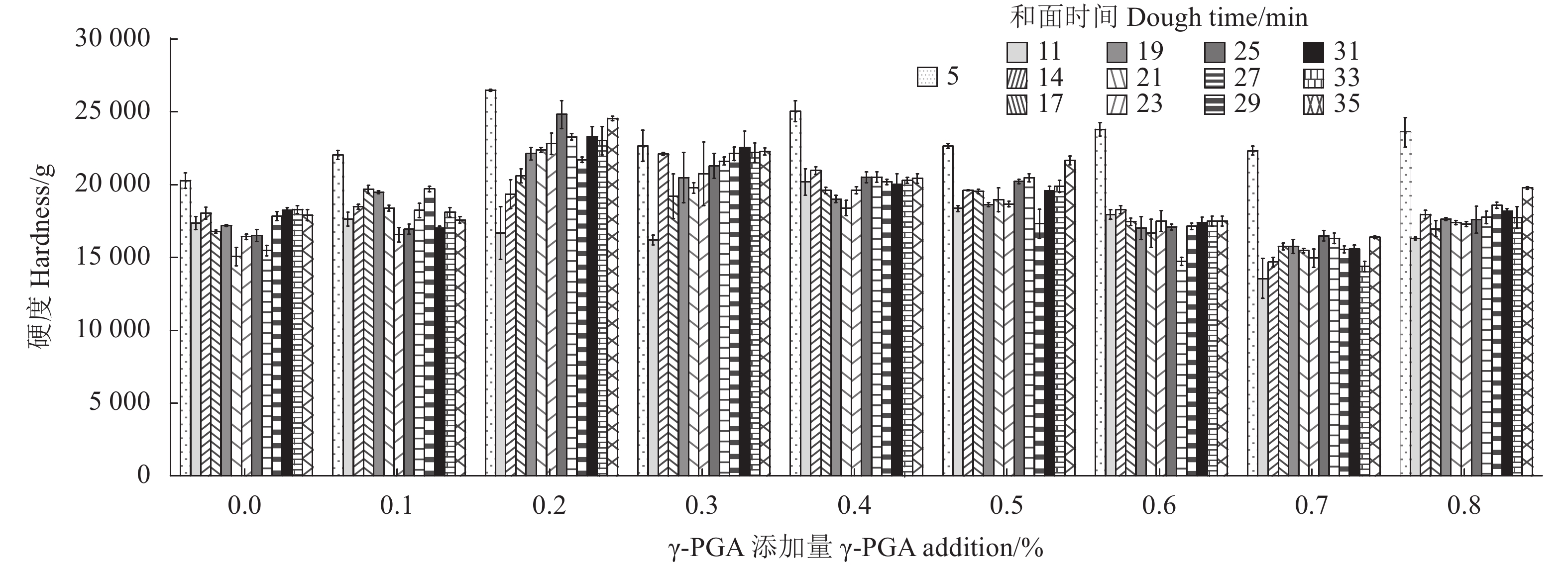

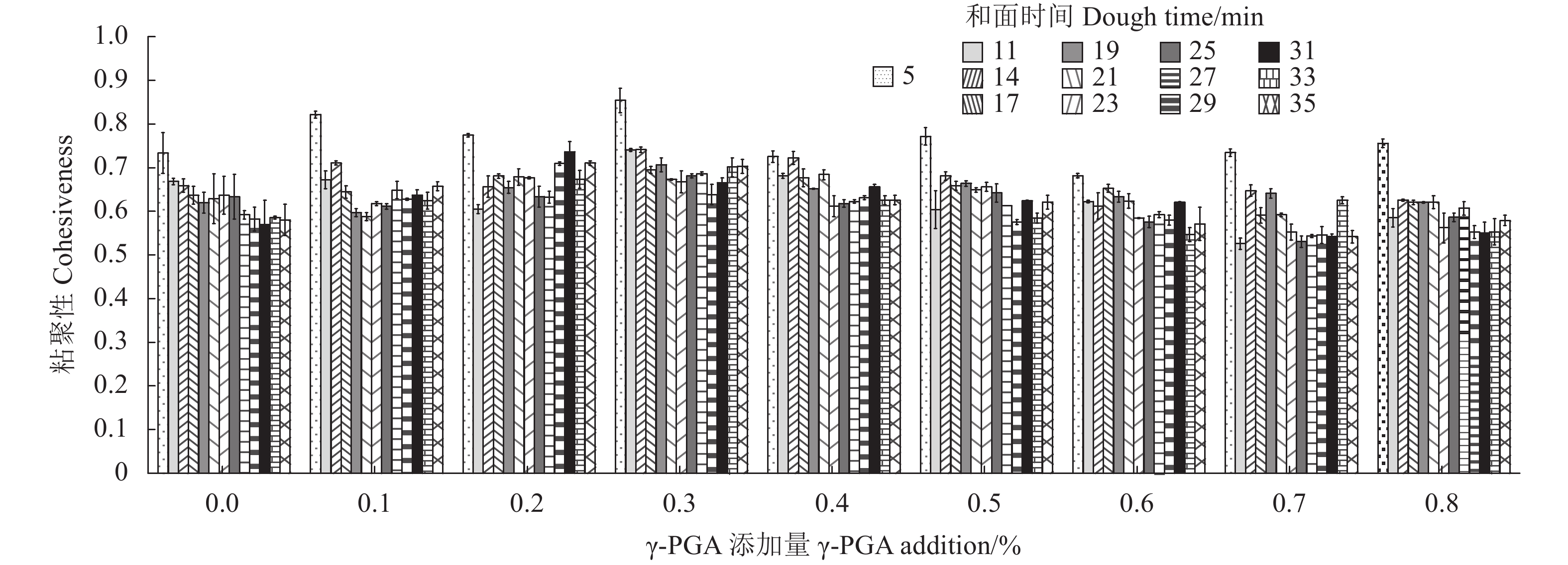

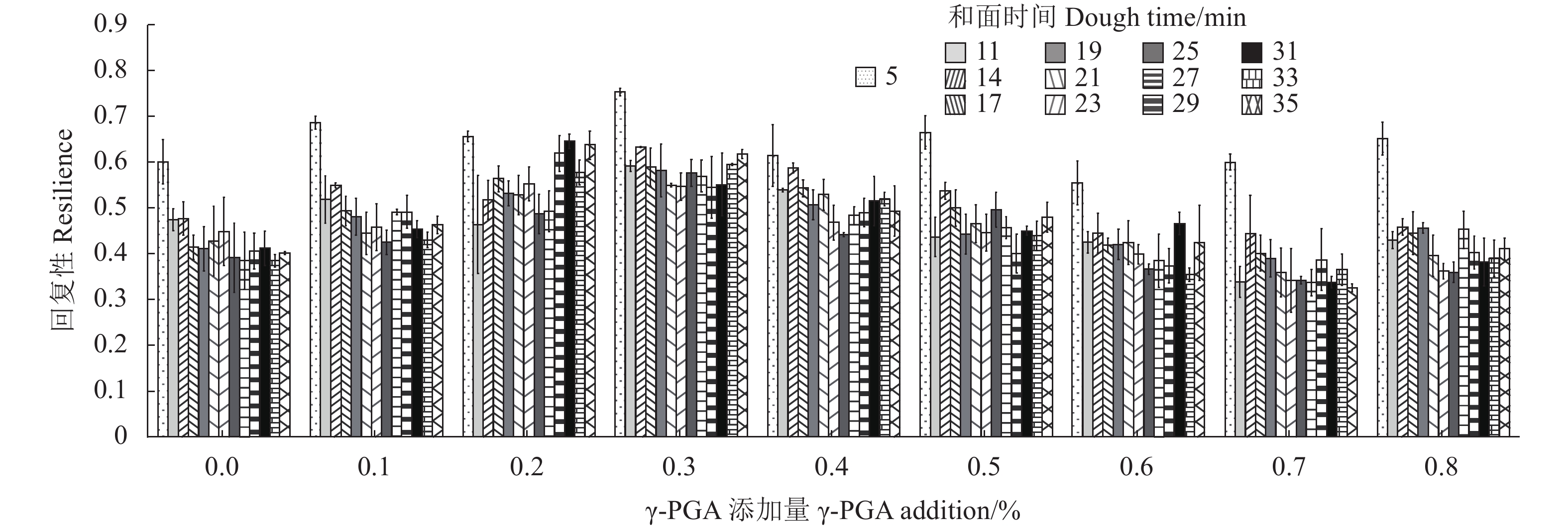

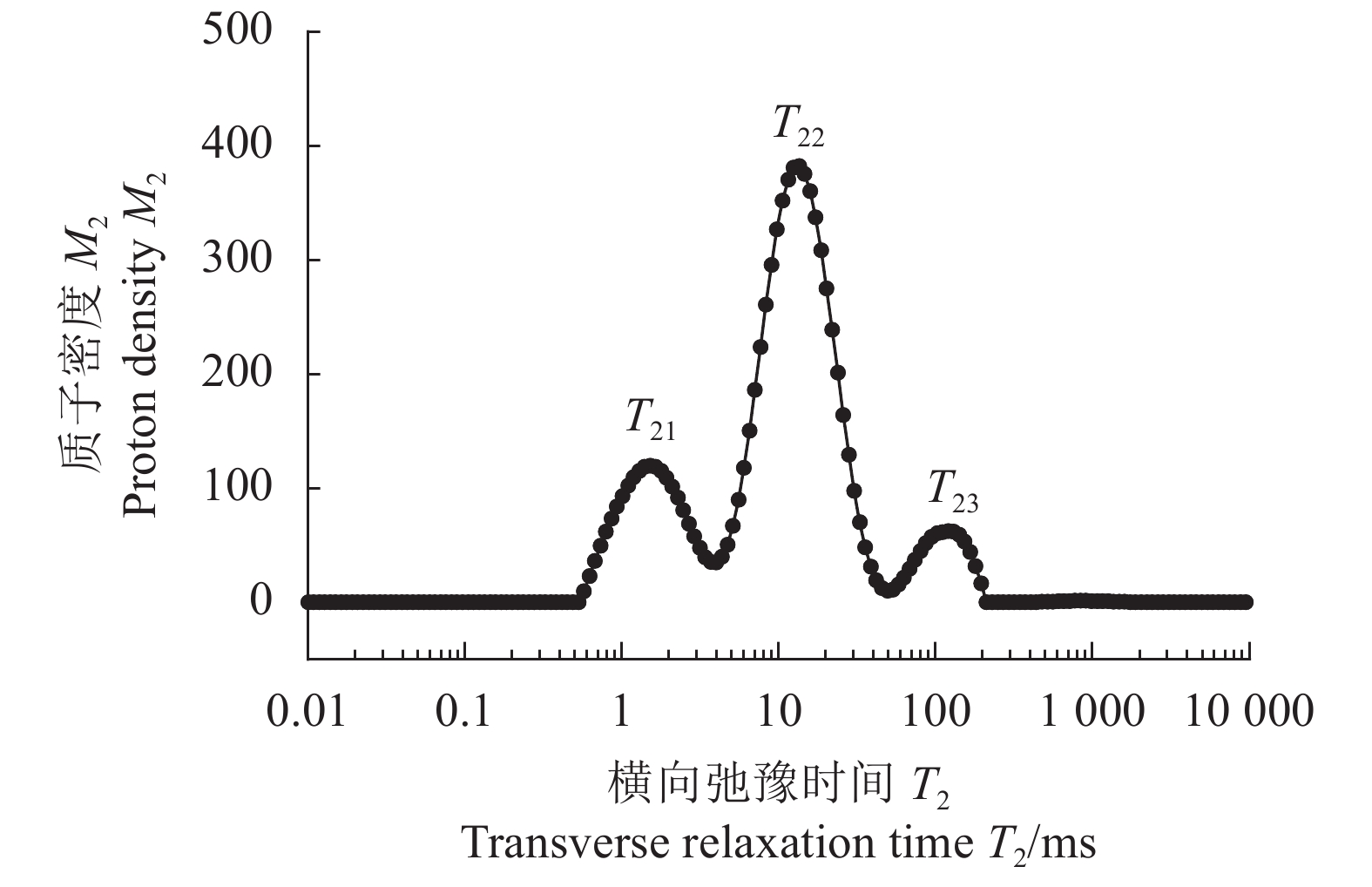

目的 了解和面过程中添加γ-聚谷氨酸对面团面筋网络结构的影响,为γ-聚谷氨酸在烘焙食品中的合理应用提供参考。 方法 以γ-聚谷氨酸的添加量为变量,利用核磁共振及核磁共振成像技术观察面团内部水分含量和状态的变化,结合质构仪和环境扫描电镜技术进一步对面团的质构特性、拉伸特性及微观结构进行分析;设置不同γ-聚谷氨酸添加量处理,在和面过程的不同时间进行取样,研究面团制作的不同阶段γ-聚谷氨酸对其面筋网络结构的影响。 结果 添加0.3%的γ-聚谷氨酸时,质子密度M21、M22最大,表明有更多的水分截留在蛋白质-淀粉形成的网络结构中;质子密度成像结果也显示出密集且均匀的红色部分;质构特性及电镜成像与核磁共振测定结果一致,并且γ-聚谷氨酸会延长面团完成时间,其面筋网络结构最稳定。试验结果表明,当γ-聚谷氨酸的添加量为0.3%、和面时间为23 min时,面团品质最佳。 结论 在面包的和面过程中添加适量的γ-聚谷氨酸,有利于提高面团的品质,但过量的γ-聚谷氨酸则会影响面团的品质。 Abstract:Objective Effect of γ-polyglutamic acid on the structure of gluten network during dough-making was studied. Method Amount ofγ-polyglutamic acid added to the dough was set as variable for the experiment. Moisture and structure of the dough were observed by nuclear magnetic resonance and magnetic resonance imaging techniques. Texture, tensile properties and microstructure of the dough were measured by a texture analyzer and an environmental scanning electron microscopy. Based on these parameters, the effects of γ-polyglutamic acid additions on the gluten network at different stages of dough formation were studied. Result At 0.3% addition of γ-polyglutamic acid in the dough, the proton density M21 and M22 peaked reaching a maximum water entrapment in the protein-starch network. The proton density imaging showed a dense and uniform red portion in the dough. The texture measurements and electron microscopy imaging displayed consistent results as did the nuclear magnetic measurements. Addition of γ-polyglutamic acid prolonged the dough-making time resulting in a most stable network structure. Conclusion An addition of γ-polyglutamic acid at 0.3% in the dough with 23 min for a complete network formation would improve, but excessive additions be detrimental to, the quality of the baked bread. -

Key words:

- γ-polyglutamic acid /

- addition /

- nuclear magnetic resonance /

- texture profile analysis /

- dough

-

图 9 γ-PGA添加量不同时面团的环境扫描电镜成像(×1 000)

注:图中a–i表示γ-PGA添加量分别为0.0%、0.1%、0.2%、0.3%、0.4%、0.5%、0.6%、0.7%、0.8%。

Figure 9. Environmental scanning electron microscope imaging of dough with varied γ-polyglutamic acid additions

Note: a–i, the addition of γ-PGA is 0.0%, 0.1%, 0.2%, 0.3%, 0.4%, 0.5%, 0.6%, 0.7%, 0.8%.

图 12 γ-PGA添加量下不同面团的质子密度成像

注:a–e:γ-PGA添加0.0%,和面时间分别为2、11、17、27和35 min;f–j:γ-PGA添加0.3%,和面时间分别为2、11、21、29 和35 min;k–o:γ-PGA添加0.7%,和面时间分别为2、11、19、23和35 min。

Figure 12. Surface proton density imaging of doughs with added γ-polyglutamic acid at 3 levels

Note:a–e:The addition of γ-PGA is 0%, the dough time is 2 , 11, 17 , 27, 35 min;f–j:The addition of γ-PGA is 0.3%, the dough time is 2, 11, 21, 29, 35 min;k–o:The addition of γ-PGA is 0.7%,the dough time is 2, 11, 19, 23, 35 min.

表 1 不同γ-PGA添加量下面团的弛豫时间T23与质构特性的相关性

Table 1. Correlation between relaxation time T23 and texture of dough with varied γ-polyglutamic acid additions

控制变量

Control variables质构特性 Texture properties 硬度 Hardness/g 粘聚性 Cohesiveness 回复性 Resilience 胶着性 Gumminess 咀嚼性 Chewiness/g T23 皮尔森相关系数 Pearson 0.278 −0.882** −0.873** −0.786* −0.519 显著性(双侧)Significant(two sides) 0.468 0.002 0.002 0.012 0.152 n 9 9 9 9 9 注:**表示在0.01水平(双侧)上显著相关;*表示在0.05水平(双侧)上显著相关。表2~4同。

Note: ** indicates significant correlation at the 0.01 level (both sides); * indicates significant correlation at the 0.05 level (both sides). The same as Table 2–4.表 2 不同 γ-PGA添加量下面团的质子密度与拉伸特性的相关性分析

Table 2. Correlation analysis of proton density and tensile properties of dough with varied γ-polyglutamic acid additions

控制变量

Control variables质子密度 Proton density M21 M22 M23 拉断力 Tensile force/g 皮尔森相关系数 Pearson 0.856** 0.682* −0.711* 显著性(双侧)Significant (two sides) 0.030 0.043 0.032 n 9 9 9 表 3 和面阶段M21变化与质构特性变化的相关性

Table 3. Correlation between M21 and texture of dough in formation

控制变量 Control variables 质构特性 Texture properties 硬度 Hardness/g 粘聚性 Cohesiveness 回复性 Resilience M21 皮尔森相关系数 Pearson 0.337 0.564* 0.620* 显著性(双侧)Significant(two sides) 0.260 0.045 0.024 n 13 13 13 表 4 γ-PGA添加量和最佳和面时间的相关性

Table 4. Correlation of γ-polyglutamic acid addition and optimal dough-formation time

控制变量

Control variables最佳和面时间

Best dough time/minγ-PGA添加量

γ-PGA addition/%皮尔森相关系数 Pearson 0.805** 显著性(双侧)

Significant(two sides)0.009 n 9 表 5 γ-PGA添加量和最佳和面时间的曲线估计

Table 5. Estimation curve for optimal dough-formation time in relation to γ-polyglutamic acid addition

方程 Equation 模型汇总 Model summary 参数估计值 Parameter estimate R2 F df1 df2 Sig. 常数 constant b1 b2 b3 线性 Linear 0.648 12.887 1 7 0.009 18.911 7.167 二次 Quadratic 0.942 49.096 2 6 0.000 16.921 24.223 −21.320 三次 Cubic 0.943 27.372 3 5 0.002 16.879 25.137 −24.351 2.525 复合 Compound 0.651 13.064 1 7 0.009 18.830 1.417 增长 Growth 0.651 13.064 7 7 0.009 2.935 0.349 指数 Exponential 0.651 13.064 7 7 0.009 18.830 0.349 逻辑 Logistic 0.651 13.064 7 7 0.009 0.053 0.706 -

[1] 李超然, 吴坤, 刘燕琪, 等. γ-聚谷氨酸对面团性质及面条质构特性的影响 [J]. 河南农业大学学报, 2014, 48(2):204−209.LI C R, WU K, LIU Y Q, et al. Effect of γ-PGA on the dough properties and noodle texture [J]. Journal of Henan Agricultural University, 2014, 48(2): 204−209.(in Chinese) [2] 范逸超, 谢新华, 沈玥, 等. γ-聚谷氨酸对小麦淀粉糊化及流变学特性的影响 [J]. 中国粮油学报, 2019, 34(5):33−37. doi: 10.3969/j.issn.1003-0174.2019.05.007FAN Y C, XIE X H, SHEN Y, et al. Effect of poly-γ-glutamic acid on the pasting and rheological properties of wheat starch [J]. Journal of the Chinese Cereals and Oils Association, 2019, 34(5): 33−37.(in Chinese) doi: 10.3969/j.issn.1003-0174.2019.05.007 [3] LIM S M, KIM J, SHIM J Y, et al. Effect of poly-γ-glutamic acids (PGA) on oil uptake and sensory quality in doughnuts [J]. Food Science and Biotechnology, 2012, 21(1): 247−252. doi: 10.1007/s10068-012-0032-2 [4] SHYU Y S, HWANG J Y, HSU C K. Improving the rheological and thermal properties of wheat dough by the addition of γ-polyglutamic acid [J]. LWT - Food Science and Technology, 2008, 41(6): 982−987. doi: 10.1016/j.lwt.2007.06.015 [5] SHYU Y S, SUNG W C. Improving the emulsion stability of sponge cake by the addition of γ-Polyglutamic acid [J]. Journal of Marine Science and Technology (Taiwan), 2010, 18(6): 895−900. [6] 赵凯亚, 姬晓月, 沈亚鹏, 等. 聚谷氨酸对油条特性与品质的影响 [J]. 河南工业大学学报(自然科学版), 2017, 38(4):75−80.ZHAO K Y, JI X Y, SHEN Y P, et al. EFFECT OF POLY-γ-GLUTAMIC ACID ON THE QUALITY OF TRADITIONAL FRIED DOUGH STICK [J]. Journal of Henan University of Technology(Natural Science Edition), 2017, 38(4): 75−80.(in Chinese) [7] 谢新华, 毋修远, 张蓓, 等. γ-聚谷氨酸对面筋蛋白功能特性的影响 [J]. 麦类作物学报, 2018, 38(8):1004−1009. doi: 10.7606/j.issn.1009-1041.2018.08.17XIE X H, WU X Y, ZHANG B, et al. Effect of γ-polyglutamic acid on functional properties of gluten protein [J]. Journal of Triticeae Crops, 2018, 38(8): 1004−1009.(in Chinese) doi: 10.7606/j.issn.1009-1041.2018.08.17 [8] 谢新华, 毋修远, 张蓓, 等. γ-聚谷氨酸对面筋蛋白冻藏稳定性的影响 [J]. 农业机械学报, 2018, 49(7):369−374. doi: 10.6041/j.issn.1000-1298.2018.07.045XIE X H, WU X Y, ZHANG B, et al. Effect of poly-γ-glutamicacid on freezing stability of gluten protein [J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 369−374.(in Chinese) doi: 10.6041/j.issn.1000-1298.2018.07.045 [9] 谢新华, 范逸超, 徐超, 等. γ-聚谷氨酸对小麦淀粉凝胶冻融稳定性的影响 [J]. 食品与发酵工业, 2019, 45(14):97−101.XIE X H, FAN Y C, XU C, et al. Effects of γ-polyglutamic acid on freeze-thaw stability of wheat starch gel [J]. Food and Fermentation Industries, 2019, 45(14): 97−101.(in Chinese) [10] 丁珊珊, 贾春利, 张峦, 等. γ-聚谷氨酸提高冷冻甜面团面包质构和感官特性研究 [J]. 食品工业科技, 2014, 35(16):308−311, 322.DING S S, JIA C L, ZHANG L, et al. Study on the enhancement of texture and sensory attributes of frozen sweet dough bread using γ-poly glutamic acid [J]. Science and Technology of Food Industry, 2014, 35(16): 308−311, 322.(in Chinese) [11] 姬晓月, 王双燕, 耿鹏, 等. γ-聚谷氨酸对速冻水饺品质的影响 [J]. 食品与发酵工业, 2018, 44(12):180−187.JI X Y, WANG S Y, GENG P, et al. Effect of poly-γ-glutamic acid on qualities of quick-frozen dumplings [J]. Food and Fermentation Industries, 2018, 44(12): 180−187.(in Chinese) [12] 宁年英, 林向阳, 林婉瑜, 等. 利用低场核磁共振研究擂溃过程对鲜猪肉糜持水性的影响 [J]. 中国食品学报, 2013, 13(2):50−59.NING N Y, LIN X Y, LIN W Y, et al. Using the low-field NMR to study the effect of blending on water holding capacity of fresh minced pork [J]. Journal of Chinese Institute of Food Science and Technology, 2013, 13(2): 50−59.(in Chinese) [13] 孙彩玲, 田纪春, 张永祥. TPA质构分析模式在食品研究中的应用 [J]. 实验科学与技术, 2007, 5(2):1−4. doi: 10.3969/j.issn.1672-4550.2007.02.001SUN C L, TIAN J C, ZHANG Y X. Application of TPA test mode in the study of food [J]. Experiment Science & Technology, 2007, 5(2): 1−4.(in Chinese) doi: 10.3969/j.issn.1672-4550.2007.02.001 [14] 李妍, 林向阳, 叶南慧, 等. 利用核磁共振技术研究海带面团面筋网络结构形成过程 [J]. 中国食品学报, 2014, 14(12):39−48.LI Y, LIN X Y, YE N H, et al. Using the low-field NMR to study the formation of gluten network structure of kelp dough [J]. Journal of Chinese Institute of Food Science and Technology, 2014, 14(12): 39−48.(in Chinese) [15] KILBORN R H, TIPPLES K H. Implications of the Mechanical Development of Bread Dough by Means of Sheeting Rolls [J]. Cereal Chemistry, 1974, 51(5): 648−657. [16] ROSS K A, PYRAK-NOLTE L J, CAMPANELLA O H. The use of ultrasound and shear oscillatory tests to characterize the effect of mixing time on the rheological properties of dough [J]. Food Research International, 2004, 37(6): 567−577. doi: 10.1016/j.foodres.2004.02.013 [17] ZHENG H, MORGENSTERN M, CAMPANELLA O, et al. Rheological properties of dough during mechanical dough development [J]. Journal of Cereal Science, 2000, 32(3): 293−306. doi: 10.1006/jcrs.2000.0339 [18] DOBRASZCZYK B, MORGENSTERN M. Rheology and the breadmaking process [J]. Journal of Cereal Science, 2003, 38(3): 229−245. doi: 10.1016/S0733-5210(03)00059-6 [19] HARASZI R, LARROQUE O R, BUTOW B J, et al. Differential mixing action effects on functional properties and polymeric protein size distribution of wheat dough [J]. Journal of Cereal Science, 2008, 47(1): 41−51. doi: 10.1016/j.jcs.2007.01.007 [20] WOODING A R, KAVALE S, MACRITCHIE F, et al. Link between mixing requirements and dough strength [J]. Cereal Chemistry Journal, 1999, 76(5): 800−806. doi: 10.1094/CCHEM.1999.76.5.800 [21] 贺建业, 冯雨丁. 面团的结构 [J]. 四川大学学报(自然科学版), 1998, 35(5):729−736.HE J Y, FENG Y D. The structure of dough [J]. Journal of Sichuan University (Natural Science Edition), 1998, 35(5): 729−736.(in Chinese) [22] 罗登林, 梁旭苹, 徐宝成, 等. 菊粉对面团中水分迁移行为的影响规律研究 [J]. 农业机械学报, 2017, 48(2):335−341. doi: 10.6041/j.issn.1000-1298.2017.02.045LUO D L, LIANG X P, XU B C, et al. Effect of inulin on moisture migration behavior in wheat dough [J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(2): 335−341.(in Chinese) doi: 10.6041/j.issn.1000-1298.2017.02.045 [23] 林向阳. 核磁共振及成像技术在面包制品加工与储藏过程中的研究[D]. 南昌: 南昌大学, 2006.LIN X Y. Study of bread during processing and storage using NMR and MRI techniques[D]. Nanchang: Nanchang University, 2006.(in Chinese) [24] SOZER N. Rheological Properties of Rice Pasta Dough Supplemented with Proteins and Gums [J]. Food Hydrocolloids, 2009, 23(3): 849−855. doi: 10.1016/j.foodhyd.2008.03.016 -

下载:

下载: