Effect of Drying Methods on Rehydration of Bacterial Cellulose

-

摘要:

目的 探究干燥方式对细菌纤维素(Bacterial cellulose,BC)复水性能的影响。 方法 采用热风干燥、微波真空干燥和真空冷冻干燥3种干燥方式干燥BC,比较不同干燥方式对BC的溶胀率和复水量的影响,并对BC微观结构进行表征。 结果 不同干燥方式会影响BC结构,引起复水性能变化。与未干燥的BC相比,冷冻干燥的BC复水率达44.79%,复水性能较其他干燥方式好;热风干燥的BC的复水性能次之;微波真空干燥的BC的复水性能最差。电子扫描电镜结果分析表明,冷冻干燥的BC纤维丝排列疏松,较好地保持了BC的表面结构,热风干燥和微波真空干燥的BC纤维排列致密。从复水性能来看,冷冻干燥方法优于2种干燥方法,且在−80 ℃冷冻后进行冷冻干燥的细菌纤维素的复水性能最好。动力学分析表明,细菌纤维素复水过程遵循Fickian扩散定律,BC的网络结构保持的越完整,材料的扩散系数越高,对应的复水性能也越好。 结论 冷冻干燥的复水性能最好。 Abstract:Objective Effects of drying methods on rehydration property of bacterial cellulose (BC) were investigated. Method BC samples dried by means of hot air, microwave under vacuum, and freeze-drying were compared on the swelling and reconstitution rates upon rehydration. A scanning electron microscope (SEM) was used to observe and characterize the BC microstructure. Result The varied dehydration processes affected the microstructure and rehydration of the dried BC. Among the untreated control and treated samples, the freeze-dried BC displayed the highest rehydration rate of 44.79%. It was followed by the hot air and the microwave-vacuum dried specimens. The SEM images showed the freeze-drying rendered BC with a loose but well-defined fibrous network, while the other two methods produced a tight structure with clusters. Insofar as hygroscopic property is concerned, freeze-drying BC at −80 ℃ was superior to all other methods. The dynamics of the water adsorption and swelling of BC followed the Fickian diffusion law. A better maintained 3D structure would have greater diffusion coefficient, and therefore, more efficient water absorption for the dried BC when water was added. Conclusion The freeze-dried BC could be rehydrated most desirably among all tested samples. The processing technology was recommended for the dehydration. -

Key words:

- Bacterial cellulose /

- hot air drying /

- microwave-vacuum drying /

- freeze drying /

- rehydration

-

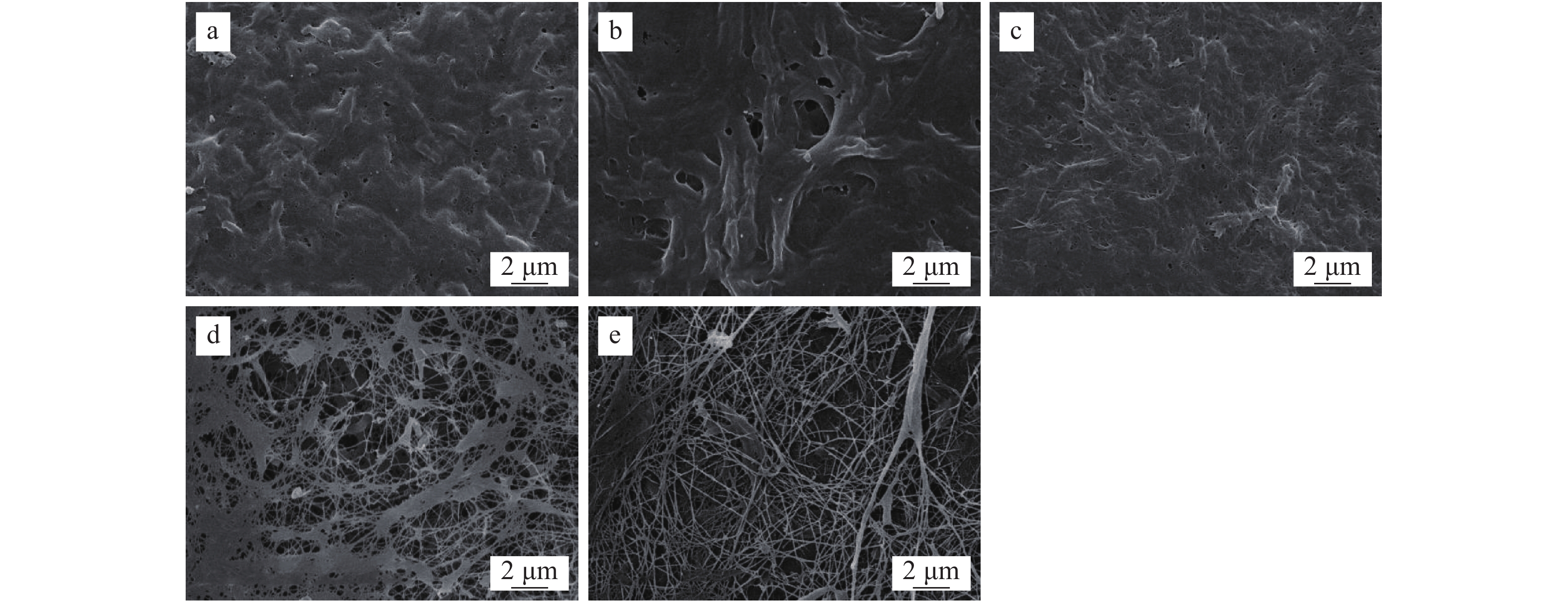

图 1 不同烘干方式烘干后的细菌纤维素的外观形态

注:a:70 ℃热风干燥;b:50 ℃热风干燥;c:微波真空干燥;d:−20 ℃预冷真空冷冻干燥;e:−80 ℃预冷真空冷冻干燥。图2同。

Figure 1. Appearances of dried BC samples

Note: a: BC-DD70: BC dehydrated by 70 ℃ hot air drying; b: BC-DD50: BC dehydrated by 50 ℃ hot air drying; c: BC-MVD: BC dehydrated by microwave-vacuum drying; d: BC-FD20: BC dehydrated by −20 ℃ freeze-drying; e: BC-FD80: BC dehydrated by −80 ℃ freeze-drying. The same as Fig.2.

图 4 细菌纤维素吸水后表观效果

注:a:70 ℃热风干燥;b:50 ℃热风干燥;c:微波真空干燥;d:−20 ℃预冷真空冷冻干燥;e:−80 ℃预冷真空冷冻干燥;f:未干燥(对照)。

Figure 4. Morphology of rehydrated BC samples

Note: a: BC-DD70: BC dehydrated by 70 ℃ hot air drying; b: BC-DD50: BC dehydrated by 50 ℃ hot air drying; c: BC-MVD: BC dehydrated by microwave-vacuum drying; d: BC-FD20: BC dehydrated by −20 ℃ freeze-drying; e: BC-FD80: BC dehydrated by −80 ℃ freeze-drying; f: untreated (CK).

表 1 不同干燥方法的细菌纤维素的吸水性能

Table 1. Water absorption of dried BC samples

样品

Samples每克干细菌纤维素的复水量

Rehydration mass of

per gram of dry bacterial

cellulose/g溶胀率

Swelling ratio/%对照 Contrast 75.11±0.11 a 7411.54±11.00 a 70 ℃热风干燥

BC-DD7018.12±0.18 e 1711.93±18.07 e 50 ℃热风干燥

BC-DD5033.74±0.24 d 3274.10±24.10 d 微波真空干燥

BC-MVD8.05±0.15 f 704.49±15.23 f −20 ℃预冷真空冷冻干燥

BC-FD2042.63±0.13 c 4162.74±12.74 c −80 ℃预冷真空冷冻干燥

BC-FD8043.79±0.19 b 4279.34±19.34 b 注:表中同列数据后不同小写字母表示差异达显著水平(P<0.05)。Note: The same column of date in the table followed by lowercase letters are significantly different (P<0.05). 表 2 不同干燥方式细菌纤维素的吸水溶胀过程的溶胀特征指数

Table 2. Rehydration indices of BC samples dried by different methods

不同干燥方式

Different drying species70 ℃ 热风干燥

BC-DD7050 ℃ 热风干燥

BC-DD50微波真空干燥

BC-MVD−20 ℃ 预冷真空冷冻干燥

BC-FD20−80 ℃ 预冷真空冷冻干燥

BC-FD80溶胀特征指数 n 0.4400 0.4942 0.3173 0.3610 0.1245 表 3 不同干燥方式细菌纤维素的吸水溶胀过程的扩散系数

Table 3. Diffusion coefficients of dried BC samples upon rehydration

不同干燥方式

Different drying species70 ℃ 热风干燥

BC-DD7050 ℃ 热风干燥

BC-DD50微波真空干燥

BC-MVD−20 ℃ 预冷真空冷冻干燥

BC-FD20−80 ℃ 预冷真空冷冻干燥

BC-FD80扩散系数 D(m2.h−1) 0.0512 0.2977 0.0013 1.5490 0.5749 -

[1] YANG Y, JIA J J, XING J R, et al. Isolation and characteristics analysis of a novel high bacterial cellulose producing strain Gluconacetobacter intermedius CIs26 [J]. Carbohydrate Polymers, 2013, 92(2): 2012−2017. doi: 10.1016/j.carbpol.2012.11.065 [2] 冯劲, 施庆珊, 冯静, 等. 不同干燥方式对细菌纤维素物理性能的影响 [J]. 现代食品科技, 2013, 29(9):2225−2229,2101.FENG J, SHI Q S, FENG J, et al. Effects of different drying processes on physical properties of bacterial cellulose membranes [J]. Modern Food Science and Technology, 2013, 29(9): 2225−2229,2101.(in Chinese) [3] 杨晨, 崔秋艳, 郑裕东, 等. 纳米细菌纤维素的不同脱水过程对结构性能的影响及再吸水动力学[J]. 高分子材料科学与工程, 2013, 29(10): 50-54YANG C, CUI Q Y, ZHENG Y D, et al. Effect of different dehydration methods on structure and property of nano bacterial cellulose and dynamics analysis of their water reabsorption[J]. Polymer Materials Science & Engineering, 2013, 29(10): 50-54. (in Chinese) [4] MIKKELSEN D, FLANAGAN B M, DYKES G A, et al. Influence of different carbon sources on bacterial cellulose production by Gluconacetobacter xylinus strain ATCC 53524 [J]. Journal of Applied Microbiology, 2009, 107(2): 576−583. doi: 10.1111/j.1365-2672.2009.04226.x [5] MACHADO R T A, GUTIERREZ J, TERCJAK A, et al. Komagataeibacter rhaeticus as an alternative bacteria for cellulose production [J]. Carbohydrate Polymers, 2016, 152: 841−849. doi: 10.1016/j.carbpol.2016.06.049 [6] LAUS M C, VAN BRUSSEL A A N, KIJNE J W. Role of cellulose fibrils and exopolysaccharides of Rhizobium leguminosarum in attachment to and infection of Vicia sativa root hairs [J]. Molecular Plant-Microbe Interactions®, 2005, 18(6): 533−538. [7] MATTHYSSE A G, THOMAS D L, WHITE A R. Mechanism of cellulose synthesis in Agrobacterium tumefaciens [J]. Journal of Bacteriology, 1995, 177(4): 1076−1081. doi: 10.1128/jb.177.4.1076-1081.1995 [8] LIN D H, LIU Z, SHEN R, et al. Bacterial cellulose in food industry: Current research and future prospects [J]. International Journal of Biological Macromolecules, 2020, 158: 1007−1019. doi: 10.1016/j.ijbiomac.2020.04.230 [9] 周伶俐, 孙东平, 吴清杭, 等. 不同培养方式对细菌纤维素产量和结构性质的影响 [J]. 微生物学报, 2007, 47(5):914−917. doi: 10.3321/j.issn:0001-6209.2007.05.032ZHOU L L, SUN D P, WU Q H, et al. Influence of culture mode on bacterial cellulose production and its structure and property [J]. Acta Microbiologica Sinica, 2007, 47(5): 914−917.(in Chinese) doi: 10.3321/j.issn:0001-6209.2007.05.032 [10] 张少瑞, 陈琳, 钟春燕, 等. 木葡糖酸醋杆菌株型对细菌纤维素产量与性能的影响 [J]. 生物过程, 2016, 6(1):8−16. doi: 10.12677/BP.2016.61002ZHANG S R, CHEN L, ZHONG C Y, et al. Effects of different Gluconacetobacter xylinus strains on yield and properties of bacterial cellulose [J]. Bioprocess, 2016, 6(1): 8−16.(in Chinese) doi: 10.12677/BP.2016.61002 [11] 罗仓学, 张岢薇, 丁勇. 干燥方法对细菌纤维素复水性能的影响[J]. 陕西科技大学学报, 2017, 35(6): 120-124, 139LUO C X, ZHANG K W, DING Y. Influence of drying methods on rehydration quality of bacterial cellulose[J]. Journal of Shaanxi University of Science & Technology, 2017, 35(6): 120-124, 139. (in Chinese) [12] 陈建福, 汪少芸, 林梅西. 海鲜菇热风干燥特性及其动力学研究 [J]. 食品工业科技, 2020, 41(3):69−73.CHEN J F, WANG S Y, LIN M X. Hot air drying characteristics and kinetics of Hypsizygus marmoreus [J]. Science and Technology of Food Industry, 2020, 41(3): 69−73.(in Chinese) [13] 张增帅, 张宝善, 罗喻红, 等. 食品微波真空干燥研究进展 [J]. 食品工业科技, 2012, 33(23):393−397.ZHANG Z S, ZHANG B S, LUO Y H, et al. Research progress of microwave vacuum drying of food [J]. Science and Technology of Food Industry, 2012, 33(23): 393−397.(in Chinese) [14] 郭雷. 真空冷冻干燥技术在我国农产品加工中的应用 [J]. 现代农业科技, 2020(3):219−220. doi: 10.3969/j.issn.1007-5739.2020.03.130GUO L. Application of vacuum freeze drying technology in agricultural products processing in China [J]. Modern Agricultural Science and Technology, 2020(3): 219−220.(in Chinese) doi: 10.3969/j.issn.1007-5739.2020.03.130 [15] LIN S B, HSU C P, CHEN L C, et al. Adding enzymatically modified gelatin to enhance the rehydration abilities and mechanical properties of bacterial cellulose [J]. Food Hydrocolloids, 2009, 23(8): 2195−2203. doi: 10.1016/j.foodhyd.2009.05.011 [16] CHEN H H, LIN S B, HSU C P, et al. Modifying bacterial cellulose with gelatin peptides for improved rehydration [J]. Cellulose, 2013, 20(4): 1967−1977. doi: 10.1007/s10570-013-9931-5 [17] 丁勇, 邵明亮, 罗仓学, 等. 热风-冷冻复式干燥细菌纤维素工艺研究 [J]. 食品科技, 2016, 41(10):228−233.DING Y, SHAO M L, LUO C X, et al. Drying processes of bacteria cellulose by combined with hot air and freezing [J]. Food Science and Technology, 2016, 41(10): 228−233.(in Chinese) [18] 章斌, 丁心, 侯小桢, 等. 柠檬片的低温冻结与真空冷冻干燥工艺研究 [J]. 食品研究与开发, 2015, 36(22):86−90. doi: 10.3969/j.issn.1005-6521.2015.22.022ZHANG B, DING X, HOU X Z, et al. Research on the processing technology of freezing and vacuum drying of lemon slices [J]. Food Research and Development, 2015, 36(22): 86−90.(in Chinese) doi: 10.3969/j.issn.1005-6521.2015.22.022 [19] GEORGE J, SAJEEVKUMAR V A, KUMAR R, et al. Enhancement of thermal stability associated with the chemical treatment of bacterial (Gluconacetobacter xylinus) cellulose [J]. Journal of Applied Polymer Science, 2008, 108(3): 1845−1851. doi: 10.1002/app.27802 [20] 赵莹婷, 王为为, 庄玮婧, 等. 莲子微波真空干燥特性及其微观结构的分形特征 [J]. 现代食品科技, 2016, 32(8):213−218.ZHAO Y T, WANG W W, ZHUANG W J, et al. Microwave vacuum drying characteristics of Lotus seeds and the fractal characteristics of their microstructures [J]. Modern Food Science and Technology, 2016, 32(8): 213−218.(in Chinese) [21] 李瑜, 许时婴. 大蒜干燥工艺的研究 [J]. 食品与发酵工业, 2004, 30(6):54−58. doi: 10.3321/j.issn:0253-990X.2004.06.013LI Y, XU S Y. Study on the technology of drying garlic [J]. Food and Fermentation Industries, 2004, 30(6): 54−58.(in Chinese) doi: 10.3321/j.issn:0253-990X.2004.06.013 [22] WAN Y Z, LUO H L, HE F, et al. Mechanical, moisture absorption, and biodegradation behaviours of bacterial cellulose fibre-reinforced starch biocomposites [J]. Composites Science and Technology, 2009, 69(7/8): 1212−1217. [23] HOSSEINI H, KOKABI M, MOUSAVI S M. Dynamic mechanical properties of bacterial cellulose nanofibres [J]. Iranian Polymer Journal, 2018, 27(6): 433−443. doi: 10.1007/s13726-018-0621-x [24] PAVALOIU R D, STOICA-GUZUN A, DOBRE T. Swelling studies of composite hydrogels based on bacterial cellulose and gelatin [J]. U. P. B. Sci. Bull. , Series B, 2015, 77(1): 53−62. -

下载:

下载: