Effect of Ultrasonic-assisted Sugar Osmotic Pretreatment on Dehydration Time and Optimization of Freeze-drying Kiwifruits

-

摘要:

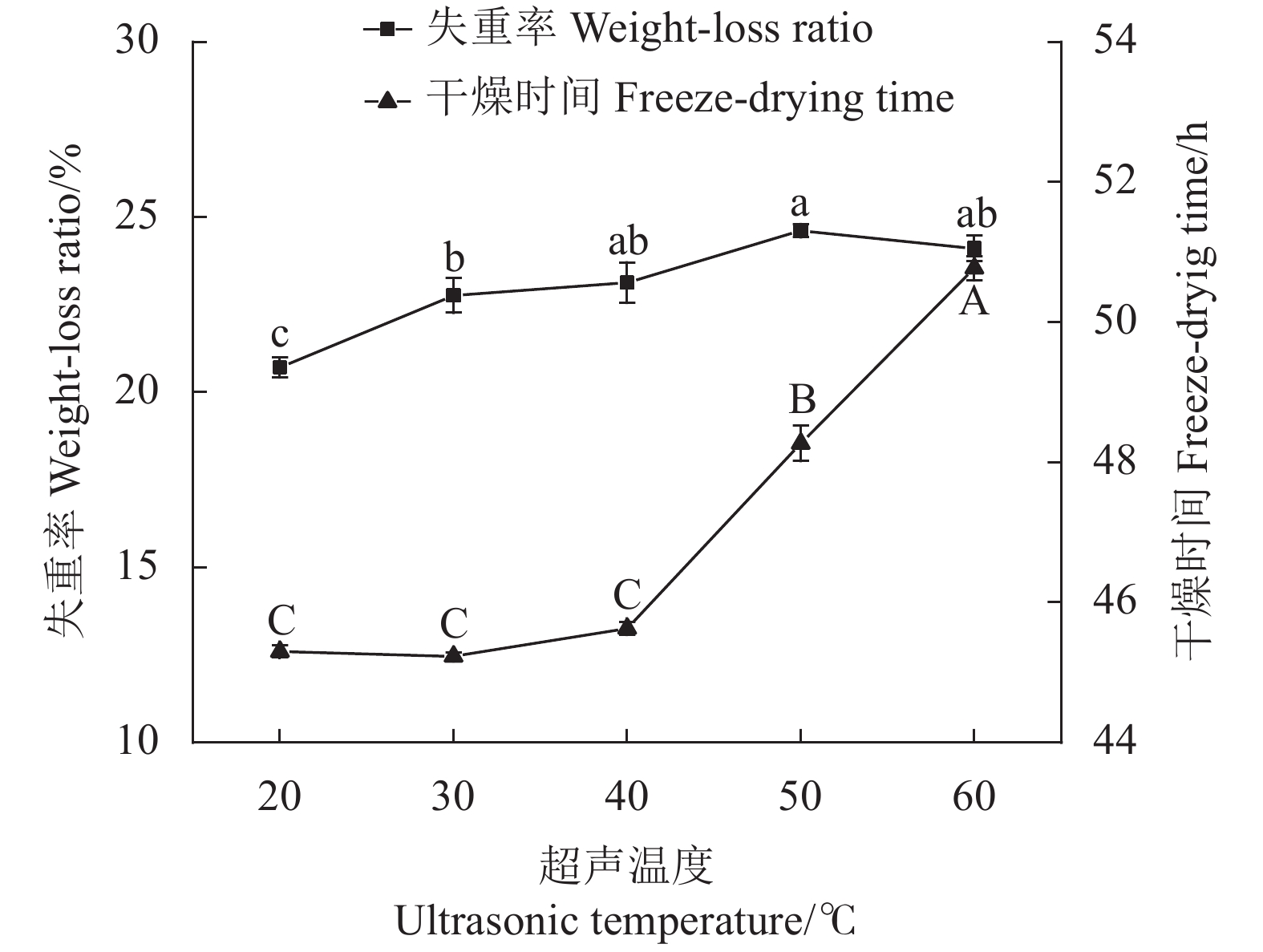

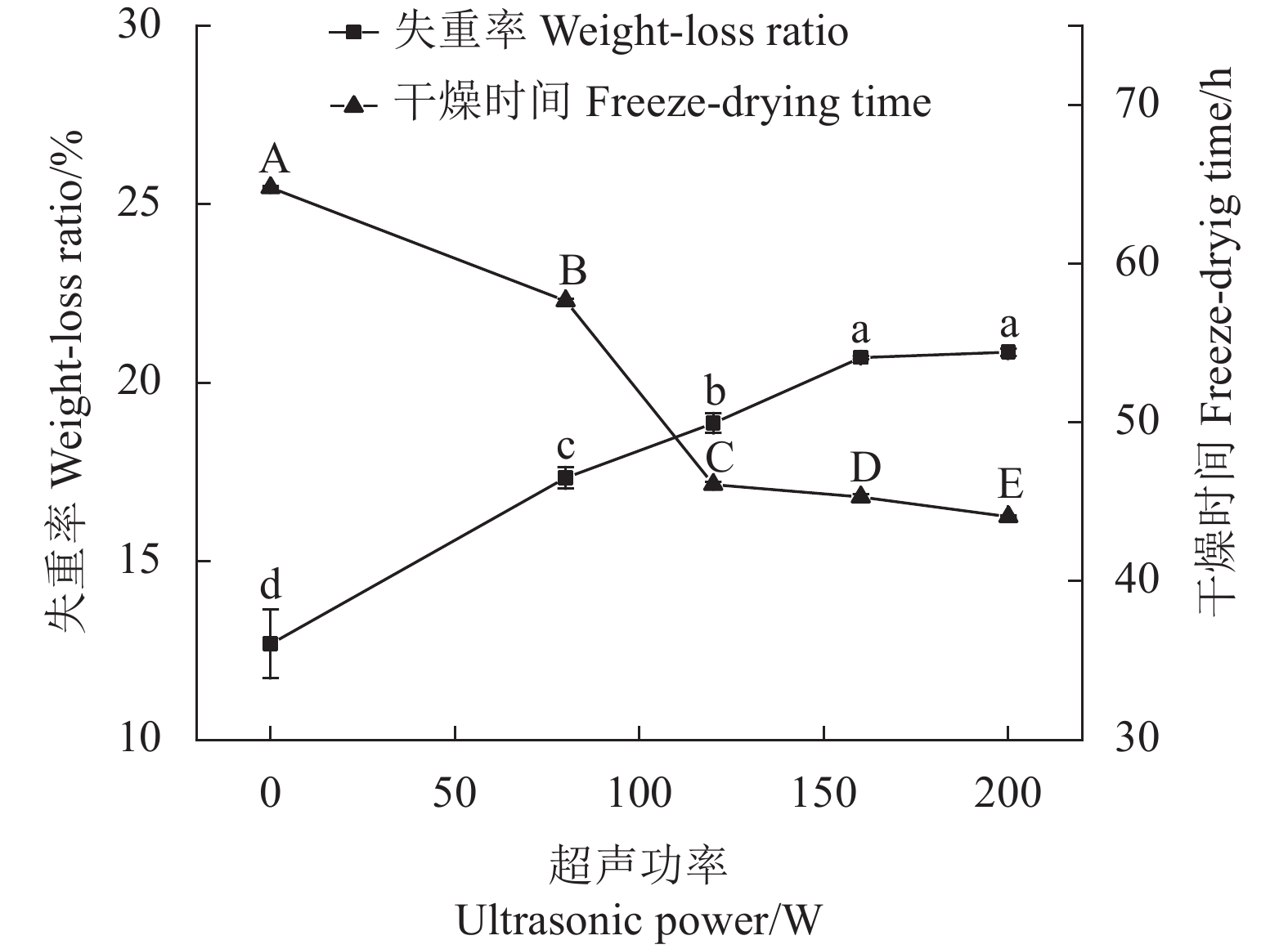

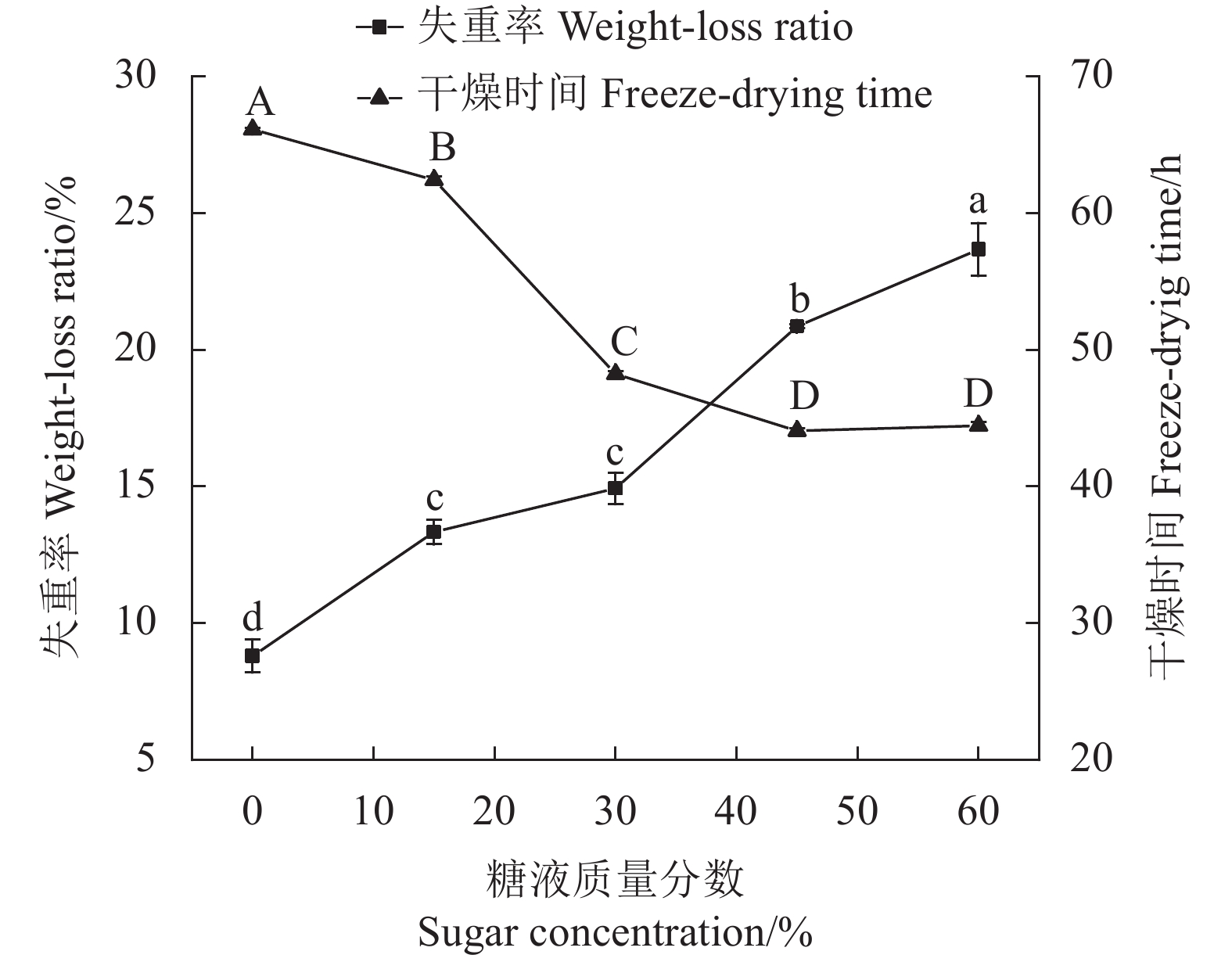

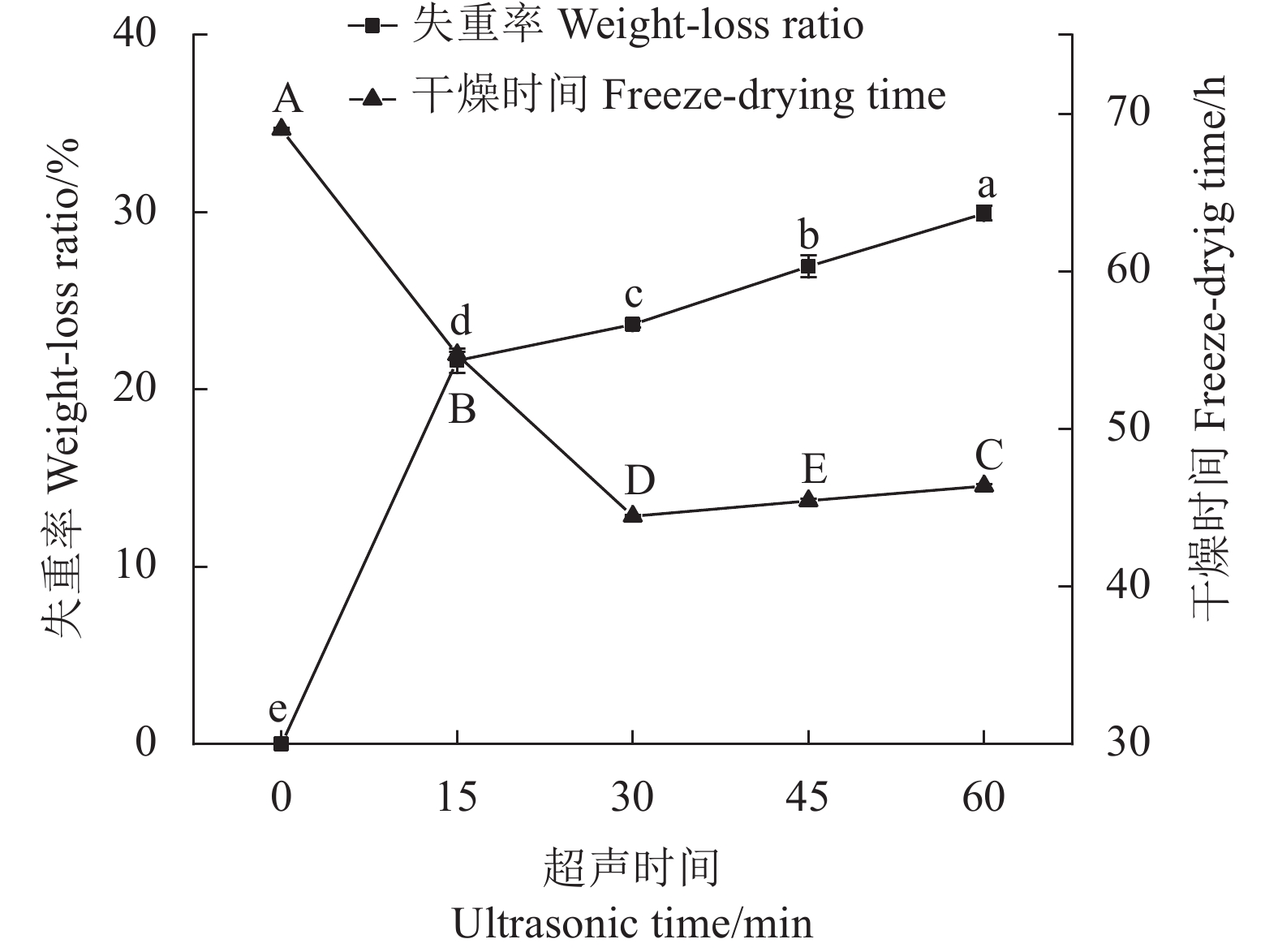

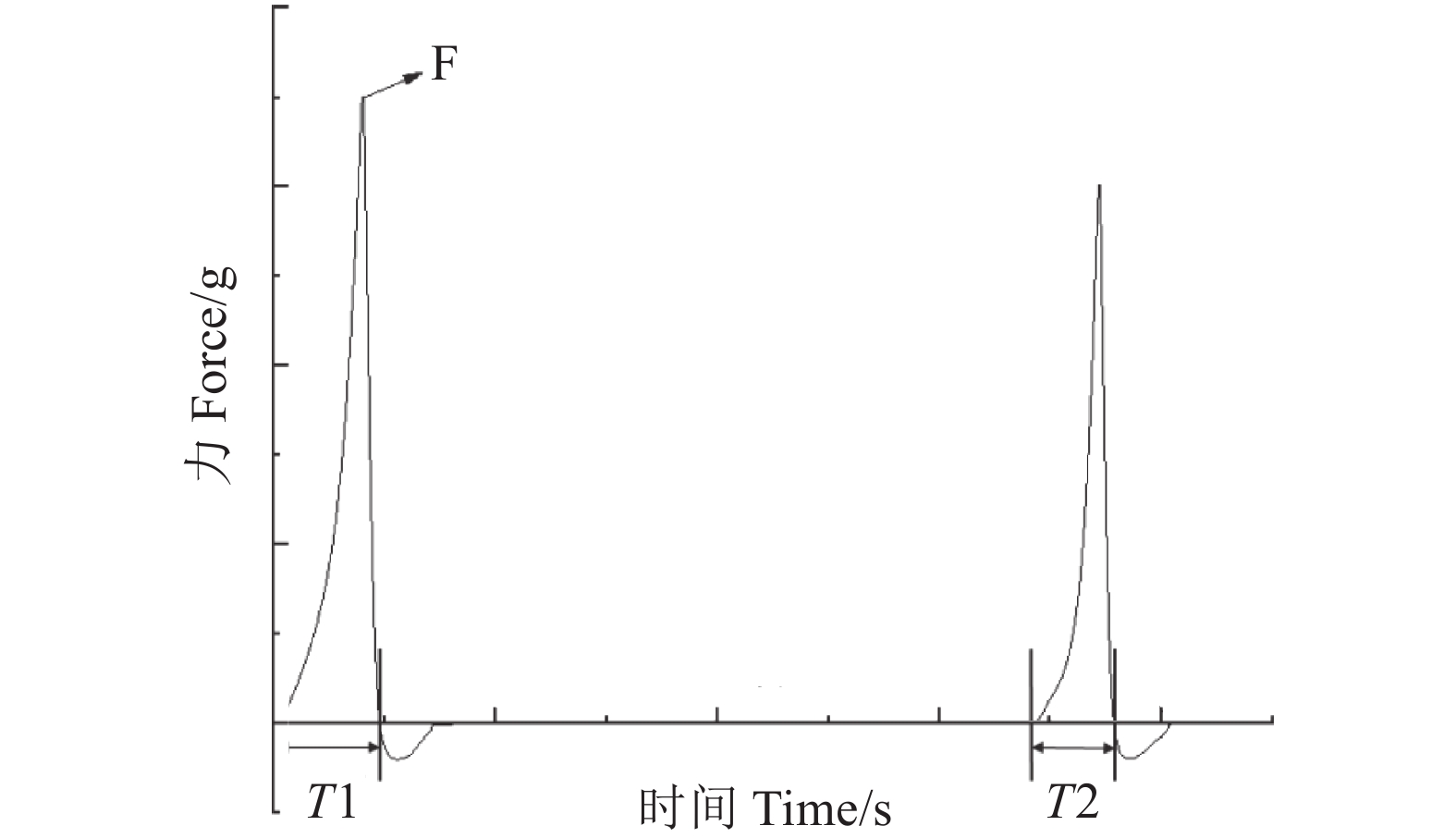

目的 优化猕猴桃渗糖工艺,缩短猕猴桃冷冻干燥时间,提高冻干猕猴桃的品质。 方法 采用单因素试验,确定理想的糖液质量分数及超声作用时间、温度和功率范围,并通过响应面法优化冻干猕猴桃的超声渗糖工艺。 结果 单因素试验表明,猕猴桃的干燥时间随着超声作用温度的增加而延长,40 ℃以上的温度会使干燥时间陡增;相反地,随着超声功率和糖液质量分数的增加,猕猴桃干燥时间整体上呈现缩短的趋势;此外,猕猴桃干燥时间随着超声作用时间的延长而缩短,并逐渐趋于稳定。响应面优化并修正后的超声渗糖最佳工艺条件:糖液质量分数45%,超声作用时间、功率和温度分别为50 min、200 W和24 ℃。该条件下猕猴桃干的干燥时间为43.07 h,硬度14616.01 g,咀嚼性7795.61 mJ,维生素C和总糖含量分别为0.19%和62.82%,并且感官品质得到进一步提升。 结论 优化后的超声渗糖工艺较传统糖渍工艺(不使用超声辅助)可显著缩短猕猴桃冻干时间,并且最终的产品质量更佳,口感更为酥脆。 Abstract:Objective The process to freeze-dry kiwifruits was optimized using an ultrasonic-assisted sugar osmotic pretreatment to shorten the drying time and improve the product quality. Method Single factor tests were conducted to determine the ranges of sugar concentration as well as ultrasonic application time, temperature, and power for the pretreatment prior to process optimization by a Box-Behnken response surface experiment. Result The time required to freeze-dry kiwifruits increased significantly when the treatment temperature was raised, especially, beyond 40℃. On the other hand, the time was shortened as the ultrasonic power and sugar concentration increased. Prolonged ultrasonic application also reduced the drying time to a leveled off minimum. The optimized pretreatment applied 200W ultrasound at 24℃ for 50m on fresh kiwifruits impinged with 45% (w/w) sugar. The freeze dehydration took 43.07h to yield kiwifruit pieces with a hardness measurement of 14,616.01g, a chewiness of 7,795.61mJ, a vitamin C content of 0.19%, and a total sugars content of 62.82%. The sensory evaluation rated the test product much superior to control without pretreatment. Conclusion The freeze-drying process optimized with ultrasonic-assisted sugar osmotic pretreatment on kiwifruits required significantly shortened dehydration time and produced products with superior quality in comparison with the conventional technology. -

表 1 感官评定标准

Table 1. Sensory evaluation standards

项目

Items分数

Score描述

Description色泽

(2.0分)

Color

(Score:2.0)1.6~2.0分

Score:1.6~2.0接近绿色,均匀一致

Close to green, uniform0.9~1.5分

Score:0.9~1.5呈浅绿色,基本一致

Light green, almost uniform0~0.8分

Score:0~0.8接近黄绿色,严重不均匀

Near yellowish green, severe unevenness滋味及气味

(3.0分)

Taste and smell

(Score:3.0)2.0~3.0 分

Score:2.0~3.0甜度适中,无异味,有猕猴桃特有的果味

Moderate sweetness, no peculiar smell, the unique fruit taste of kiwifruit1.0~1.9分

Score:1.0~1.9甜度适中,无异味,猕猴桃的果味不够明显

Moderate sweetness, no peculiar smell, the unique fruit taste of kiwifruit was not obvious0~0.9分

Score:0~0.9过酸或过甜,有异味

Too sour or too sweet, smelly组织形态

(2.0分)

Structure

(Score:2.0)1.6~2.0 分

Score:1.6~2.0硬度适中,无气泡,薄厚适宜

Moderate hardness, no bubbles, suitable thickness0.9~1.5分

Score:0.9~1.5偏硬或偏软,少量气泡,薄厚不均匀

Hard or soft, a few bubbles, uneven thickness0~0.8分

Score:0~0.8严重偏软或偏硬,大量气泡,过薄或过厚

Severe soft or hard, lots of bubbles, too thin or too thick口感

(3.0分)

Mouthfeel

(Score:3.0)2.0~3.0分

Score:2.0~3.0口感酥脆,适口

Crispy and palatability1.0~1.9 分

Score:1.0~1.9口感较酥脆,较适口

Almost crisp and palatability0~0.9分

Score:0~0.9口感不酥脆,不适口

Not crisp and palatability表 2 Box-Behnken试验因素水平

Table 2. Factors and levels of Box-Behnken experiment

因素

Factor水平 Levels −1 0 1 A:超声时间

A:ultrasonic time/min30 45 60 B:超声功率

B:ultrasonic power/W120 160 200 C:超声温度

C:ultrasonic temperature/℃20 30 40 D:糖液质量分数

D:sugar concentration/%30 45 60 表 3 Box-Behnken试验设计及结果

Table 3. Design and results of Box-Behnken experiment

序号

No.A:超声

时间

A:ultrasonic time/

minB:超声

功率

B:ultrasonic power/

WC:超声

温度

C:ultrasonic temperature/

℃D:糖液

质量分数

D:sugar concentration/

%冷冻干燥时间

Freeze-drying

time/h1 30 160 30 60 48.2 2 60 160 40 45 45.1 3 45 200 30 60 45.0 4 60 160 20 45 45.3 5 60 160 30 60 46.4 6 45 120 40 45 46.1 7 45 160 30 45 43.8 8 45 120 30 30 48.4 9 30 120 30 45 47.6 10 45 160 20 30 45.8 11 30 160 40 45 45.7 12 30 160 30 30 48.0 13 60 160 30 30 46.5 14 45 160 40 60 46.0 15 45 160 30 45 44.1 16 45 200 40 45 43.9 17 45 120 20 45 46.5 18 45 200 20 45 43.1 19 45 160 30 45 44.0 20 45 120 30 60 48.3 21 60 200 30 45 43.0 22 45 160 40 30 45.9 23 60 120 30 45 46.5 24 30 200 30 45 45.0 25 45 160 20 60 45.7 26 45 200 30 30 45.6 27 30 160 20 45 45.5 表 4 回归模型的方差分析结果及显著性检验

Table 4. Analysis of variance and significance test

方差

来源

Source平方和

Sum of

squares自由

度

df均方

Mean

squareF值

F valueP值

(Pr>F)

P value

(Pr>F)显著性

Significance模型

Model57.68 14 4.12 23.71 <0.0001 ** A 4.32 1 4.32 24.86 0.30×10−3 * B 26.40 1 26.40 151.96 <0.0001 ** C 0.05 1 0.05 0.31 0.59 D 0.03 1 0.03 0.17 0.69 AB 0.20 1 0.20 1.17 0.30 AC 0.04 1 0.04 0.23 0.64 AD 0.02 1 0.02 0.13 0.73 BC 0.36 1 0.36 2.07 0.18 BD 0.06 1 0.06 0.36 0.56 CD 0.01 1 0.01 0.06 0.81 A2 7.10 1 7.10 40.89 <0.0001 ** B2 2.46 1 2.46 14.16 0.002 * C2 0.09 1 0.09 0.519 0.49 D2 21.96 1 21.96 126.39 <0.0001 ** 残差

Residual2.085 12 0.17 失拟项

Lack of

fit2.04 10 0.20 8.74 0.11 纯误差

Pure error0.05 2 0.02 R2=0.9651,RAdj2=0.9244;P<0.0001为高度显著,用“**”表示;P<0.05为显著,用“*”表示。

R2=0.965 1; RAdj2=0.924 4; Significant difference at P< 0.0001 is highly significant, denoted by "**"; significant difference at P< 0.05 is significant, denoted by "*" .表 5 响应面优化前后猕猴桃干品质指标

Table 5. Quality indicators of kiwifruits freeze-dried with and without process optimization

样品名称

Sample name糖渍样品

Sample produced

without the assistance

of ultrasonic超声渗糖样品

Sample produced

by ultrasonic-assisted

sugar osmotic process干燥时间

Freeze-drying time/h64.00±0.08 a 43.07±0.02 b 水分含量

Moisture content/%5.92±0.06 a 5.83±0.04 a 维生素C含量

Vitamin C content/%0.13±0.03 a 0.19±0.04 b 感官得分

Sensory evaluation score8.06±0.39 b 8.29±0.43 a 总糖含量

Total sugar content/%68.57±0.25 a 62.82±0.22 b 总酸含量

Total acid content/%2.13±0.01 b 2.24±0.01 a 糖酸比

Sugar-acid ratio32.16±0.01 a 28.07±0.01 b 硬度

Hardness/g17650.29±1247.39 a 14616.01±981.81 b 咀嚼性

Chewiness/mJ8851.40±1025.83 a 7795.61±1019.65 b 同行数据后不同小写字母表示差异显著(t检验,P<0.05)。

Date with different letters on same row indicate significant differences at P<0.05, using the t test. -

[1] 王英珍, 潘芝梅. 二十二份毛花猕猴桃种质资源果实品质的主成分分析与综合评价 [J]. 浙江农业学报, 2021, 33(5):825−830. doi: 10.3969/j.issn.1004-1524.2021.05.07WANG Y Z, PAN Z M. Comprehensive evaluation of 22 Actinidia Eriantha germplasm resources based on princal components analysis [J]. Journal of Zhejiang Agriculture, 2021, 33(5): 825−830.(in Chinese) doi: 10.3969/j.issn.1004-1524.2021.05.07 [2] TRAFFANO-SCHIFFO M V, LAGHI L, CASTRO-GIRADEZ M, et al. Osmotic dehydration of organic kiwifruit pretreated by pulsed electric fields and monitored by NMR [J]. Food Chemistry, 2017, 236: 87−93. doi: 10.1016/j.foodchem.2017.02.046 [3] 陈志伟, 戢小梅, 李秀丽, 等. 猕猴桃贮藏及加工研究进展 [J]. 农业与技术, 2019, 39(24):38−45.CHEN Z W, JI X M, LI X L, et al. Research progress of kiwifruit storage and processing [J]. Agriculture and Technology, 2019, 39(24): 38−45.(in Chinese) [4] 王新珂, 杨锡洪, 吴帆, 等. 果蔬冷冻干燥节能新技术研究进展 [J]. 食品与机械, 2020, 36(6):226−232.WANG X K, YANG X H, WU F, et al. Research progress on the new freeze-drying technology of fruits and vegetables [J]. Food and Machinery, 2020, 36(6): 226−232.(in Chinese) [5] 罗登林, 苏孟开, 杨日福, 等. 超声在食品干燥领域中的研究进展 [J]. 中国粮油学报, 2020, 35(5):188−196.LUO D L, SU M K, YANG R F, et al. Progress of food drying assisted by ultrasound [J]. Journal of the Chinese Cereals and Oils Association, 2020, 35(5): 188−196.(in Chinese) [6] 陈腊梅, 金鑫, 毕金峰, 等. 超声辅助糖液渗透处理对真空冷冻干燥桃脆片干制品品质及吸湿性的影响[J/OL]. 食品科学, 1-11[2021-09-16]. http://kns.cnki.net/kcms/detail/11.2206.ts.20210816.1140.012.html.CHEN L M, JIN X, BI J F, et al. Effect of ultrasonic assisted sugar osmotic pretreatment on quality and hygroscopicity of vacuum freeze dried peach chips[J/OL]. Food Science, 1-11[2021-09-16]. http://kns.cnki.net/kcms/detail/11.2206.ts.20210 816.1140.012.html.(in Chinese) [7] 孙宝芝, 姜任秋, 淮秀兰, 等. 声空化强化渗透脱水 [J]. 化工学报, 2004, 10:1714−1718. doi: 10.3321/j.issn:0438-1157.2004.10.013SUN B Z, JIANG R Q, HUAI X L, et al. Enhancing osmotic dehydration with acoustic cavitation. [J]. Journal of Chemical Industy and Engineering, 2004, 10: 1714−1718.(in Chinese) doi: 10.3321/j.issn:0438-1157.2004.10.013 [8] TAO Y, WANG P, WANG Y L, et al. Power ultrasound as a pretreatment to convective drying of mulberry (Morus Alba L) leaves: Impact on drying kinetics and selected quality properties [J]. Ultrasonics Sonochemistry, 2016, 31: 310−318. doi: 10.1016/j.ultsonch.2016.01.012 [9] RICCE C, ROJAS M L, MIANO A C, et al. Ultrasound pretreatment enhances the carrot drying and rehydration [J]. Food Research International, 2016, 89: 701−708. doi: 10.1016/j.foodres.2016.09.030 [10] CORREA J L G, PEREIRA L M, VIERIA G S, et al. Mass transfer kinetics of pulsed vacuum osmotic dehydration of guavas [J]. Journal of Food Engineering, 2010, 96(4): 498−504. doi: 10.1016/j.jfoodeng.2009.08.032 [11] SALAZAR-LOPEZ E I, JIMENEZ M, SALAZAR R, et al. Incorporation of microcapsules in pineapple intercellular tissue using osmotic dehydration and micro-encapsulation method [J]. Food and Bioprocess Technology, 2015, 8(8): 1699−1706. doi: 10.1007/s11947-015-1534-8 [12] PRITHANI R, DASHK K. Mass transfer modelling in ultrasound assisted osmotic dehydration of kiwifruit [J]. Innovative Food Science and Emerging Technologies, 2020, 64: 102407. doi: 10.1016/j.ifset.2020.102407 [13] BOZKIR H, ERGUN A R, SERDAR E, et al. Influence of ultrasound and osmotic dehydration pretreatments on drying and quality properties of persimmon fruit [J]. Ultrasonics Sonochemistry, 2019, 54: 135−141. doi: 10.1016/j.ultsonch.2019.02.006 [14] FONG-IN S, NINITKEATKAI H, PROMMAJAK T, et al. Ultrasound-assisted osmotic dehydration of litchi: Effect of pretreatment on mass transfer and quality attributes during frozen storage [J]. Journal of Food Measurement and Characterization, 2021, 15(4): 3590−3597. doi: 10.1007/s11694-021-00931-9 [15] SANTACATALINA J V, CONTRERAS M, SIMAL S, et al. Impact of applied ultrasonic power on the low temperature drying of apple [J]. Ultrasonics Sonochemistry, 2016, 28: 100−109. doi: 10.1016/j.ultsonch.2015.06.027 [16] 马宏飞, 卢生有, 韩秋菊, 等. 紫外分光光度法测定五种果蔬中维生素C的含量 [J]. 化学与生物工程, 2012, 29(8):92−94.MA H F, LU S Y, HAN Q J, et al. Determination of vitamin C content in five kinds of fruits and vegetables by UV spectrophotometry [J]. Chemistry and Bioengineering, 2012, 29(8): 92−94.(in Chinese) [17] 曹建康, 姜微波, 赵玉梅, 等. 果蔬采后生理生化实验指导[M]. 北京: 中国轻工业出版社, 2017: 28—37. [18] 马空军, 贾殿赠, 包文忠, 等. 超声场强化渗透脱水传质机理模型研究 [J]. 食品科学, 2011, 32(13):94−101.MA K J, JIA D Z, BAO W Z, et al. Mass transfer mechanism and mathematical model for ultrasonic-enhanced osmotic dehydration [J]. Food Science, 2011, 32(13): 94−101.(in Chinese) [19] 刘云宏, 吴建业, 刘建学, 等. 超声渗透脱水-热风干燥梨的研究 [J]. 食品科学, 2014, 35(3):23−28. doi: 10.7506/spkx1002-6630-201403005LIU Y H, WU J Y, LIU J X, et al. Ultrasonic-assisted osmotics dehydration and subsequent hot-air drying of pear slices [J]. Food Science, 2014, 35(3): 23−28.(in Chinese) doi: 10.7506/spkx1002-6630-201403005 [20] 陈立夫, 裴斐, 张里明, 等. 超声辅助渗透处理对冷冻干燥双孢蘑菇冻干效率和品质的影响 [J]. 食品科学, 2017, 38(23):8−13. doi: 10.7506/spkx1002-6630-201723002CHEN L F, PEI F, ZHANG L M, et al. Effect of ultrasound-assisted osmotic pretreatment on freeze-drying efficiency and quality of agaricus bisporus [J]. Food Science, 2017, 38(23): 8−13.(in Chinese) doi: 10.7506/spkx1002-6630-201723002 [21] 郑丽静, 聂继云, 闫震. 糖酸组分及其对水果风味的影响研究进展 [J]. 果树学报, 2015, 32(2):304−312.ZHENG L J, NIE J Y, YAN Z. Advances in research on sugars, organic acids and their effects on taste of fruits [J]. Journal of Fruit Science, 2015, 32(2): 304−312.(in Chinese) [22] 宋悦, 金鑫, 毕金峰, 等. 超声辅助渗透处理对热风干燥及真空冷冻干燥黄桃片品质的影响 [J]. 食品科学, 2020, 41(15):177−185. doi: 10.7506/spkx1002-6630-20190730-403SONG Y, JIN X, BI J F, et al. Effect of ultrasonic-assisted osmotic dehydration on the quality characteristics of hot air dried and vacuum freeze dried yellow peach chips [J]. Food Science, 2020, 41(15): 177−185.(in Chinese) doi: 10.7506/spkx1002-6630-20190730-403 [23] 曾祥媛, 赵武奇, 卢丹, 等. 超声波对猕猴桃片的渗糖效果及干燥能耗与品质的影响 [J]. 中国农业科学, 2019, 52(4):725−737.ZENG X Y, ZHAO W Q, LU D, et al. Effects of ultrasound on the sugar permeability effect, drying energy consumption and quality of kiwifruit slices [J]. Scientia Agricultura Sinica, 2019, 52(4): 725−737.(in Chinese) [24] 王忠合, 王军, 林倩仪. 超声辅助热风干燥柠檬片的动力学研究及其维生素C含量的变化 [J]. 中国食品学报, 2020, 20(4):187−196.WANG Z H, WANG J, LIN J Y, et al. Kinetic study of ultrasonic-assisted hot air drying of lemon slices and changes in vitamin C content [J]. Journal of Chinese Institute of Food Science and Technology, 2020, 20(4): 187−196.(in Chinese) -

下载:

下载: