Dehydration Isotherm and Vitality Kinetics of Dried Saccharomyces cerevisiae

-

摘要:

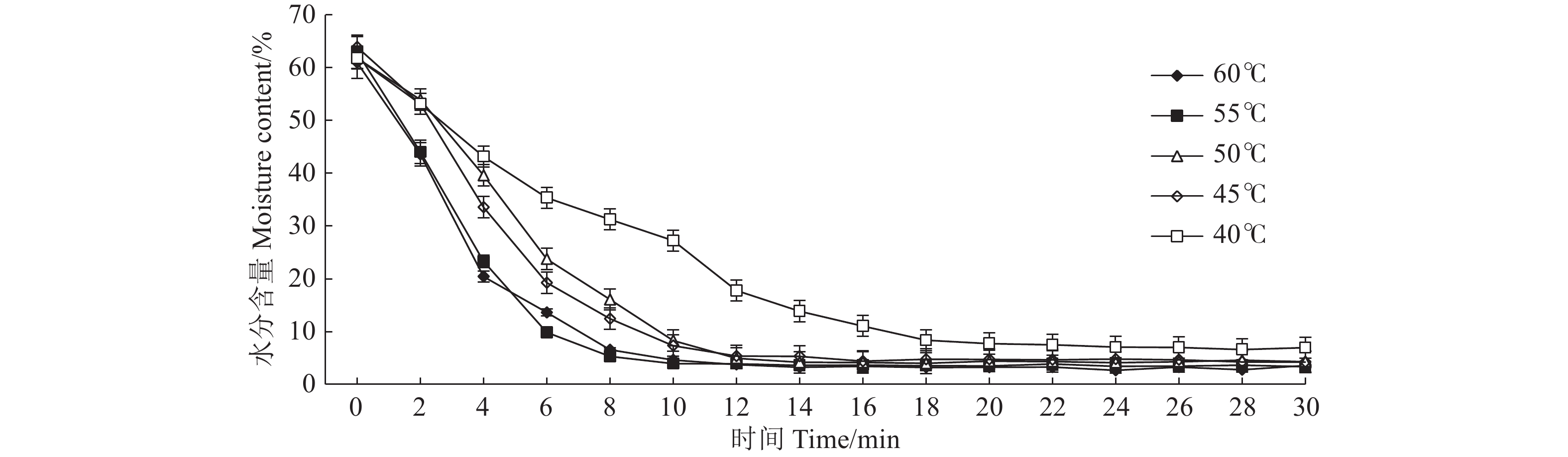

目的 为高活力酿酒酵母直投式发酵剂的研发提供理论和技术支持。 方法 以酿酒酵母JH301为研究对象,采用沸腾炉热风干燥技术制备菌剂,研究不同温度下酿酒酵母沸腾炉热风干燥过程水分含量、菌存活率的变化及其相关性,建立酿酒酵母菌剂等温干燥曲线及其存活率干燥动力学模型,并采用核磁共振技术考察酵母菌沸腾炉热风干燥过程水分迁移分布规律。 结果 (1)酿酒酵母菌剂沸腾炉热风干燥过程等温干燥曲线符合Henderson指数函数模型M=a×EXP(b×T),a、b均为与干燥温度W相关的常数。(2)随着干燥过程菌剂水分含量的下降,菌存活率呈先平缓下降后快速下降趋势,存在菌存活率拐点水分阈值。在拐点水分阈值前后,菌存活率干燥动力学模型分别符合模型y前=a前x+b前、y后=a后x+b后,a、b均为与温度(W)相关的常数。y前与y后的交叉点即为菌存活率拐点水分阈值,菌存活率拐点水分阈值与干燥温度呈正相关,菌存活率与细胞结合水的逃逸速率呈负相关。(3)菌存活率拐点水分阈值的最低干燥温度理论值为41.2 ℃。通过对模型参数预测与验证,适宜的干燥温度为42 ℃,时间为20 min,菌剂水分含量为(5.24±0.12)%,菌存活率可达(48.24±0.15)%。 结论 通过调控热风干燥过程酿酒酵母结合水的逃逸速率,可提高菌存活率。 Abstract:Objective Isotherm of dehydration process and kinetics of survival rate of a dried Saccharomyces cerevisiae product were studied for the development of a highly active yeast product with extended shelf life for vinification. Method S. cerevisiae JH301 was used in the fluidized hot air oven dehydration experimentation. Under varied hot air temperatures, the moisture content and survival rate of S. cerevisiae were monitored to construct dehydration isotherms and analyze yeast vitality. Water migration and distribution in the drying yeasts were determined by a nuclear magnetic resonance mothed. Results (1) The dehydration isotherm followed the Henderson exponential equation of M=a×EXP(b×T), where a and b were the constants related to the drying temperature (W) as a=−0.31W+81.36 and b= −0.009 4W+0.27. (2) The yeast survival rate declined gradually at first, and then, rapidly as the moisture content decreased with time in the process. A water threshold appeared at the inflection point of the yeast survival rate curve. The kinetic equations before the threshold point were y1= a1x+b1, and after the point y2= a2x+b2, where a1=0.014W+0.20, b1=−0.90W+81.64, a2=0.36W−14.04, and b2=−2.77W+159.40. The moisture content at the point where y1 and y2 intersected, or the water threshold, positively correlated with the processing hot air temperature, while the yeast survival rate negatively correlated with the rate of bounded water evaporated from the yeast cells. (3) A theoretical minimum drying temperature was determined to be 41.2 ℃. Based on the kinetic model prediction and a follow-up experimental verification, the optimal yeast dehydration was determined to be conducted at 42 ℃ for 20 min. A final moisture content of (5.24±0.12)% with a survival rate of (48.24±0.15)% on the dried yeast product was achieved. Conclusion The vitality of the dried S. cerevisiae could be maximized by controlling the evaporation of bounded yeast cellular water in the hot air dehydration process. -

表 1 不同干燥温度菌存活率拐点水分阈值的模型预测值

Table 1. Predicted water threshold at inflection point on kinetic equations of S. cerevisiae survival rate under different drying temperatures

干燥温度

Temperature/℃干燥时间

Time/min菌存活率拐点水分阈值

Water threshold inflection

point of survival

rate of strains/%菌存活率

Survival rate

of strains/%60 8.3 5.28 33.22 55 10.0 5.25 37.35 50 12.5 5.17 41.44 45 16.7 4.90 45.37 42 23.9 3.15 46.42 表 2 热风干燥过程酵母菌剂理化指标的变化

Table 2. Changes on physiochemical indices of S. cerevisiae during hot air dehydration

干燥温度

Temperature/℃干燥时间

Time/min水分含量

Moisture

content/%结合水含量

Combined

water content/Au束缚水含量

Bound water

content/Au自由水含量

Free water

content/Au菌存活率

Survival rate of

strains/%结合水逃逸速率

Escape rate of

combined water/(Au·min−1)45 12 7.33±0.12 1649.06±25.34 700.02±36.82 369.41±5.47 49.72±0.32 0.02±0.00 14 5.31±0.36 1255.67±38.63 947.65±38.03 267.42±15.25 46.12±0.06 28.11±2.15 16 4.40±0.06 1087.21±23.44 911.21±45.45 229.07±25.51 42.01±0.06 35.13±2.18 50 10 8.30±0.24 1634.83±15.85 457.72±15.19 239.38±23.99 45.06±0.00 1.44±0.01 12 4.96±0.18 1053.79±43.64 982.08±42.74 198.16±28.16 41.00±0.16 49.62±0.73 14 4.17±0.06 761.07±25.34 934.04±28.51 158.20±21.35 36.02±0.32 63.44±1.15 55 8 9.84±0.12 1627.97±37.44 777.24±13.28 298.61±23.34 40.89±0.32 2.66±0.10 10 5.29±0.06 933.68±33.68 859.06±35.46 264.82±17.13 37.31±0.06 71.56±1.12 12 3.95±0.06 643.76±12.77 850.28±35.31 123.76±12.33 29.74±0.32 83.79±1.03 60 8 6.55±0.18 1197.14±15.31 806.91±18.64 260.68±10.65 38.17±0.06 56.52±2.12 10 4.63±0.18 844.76±22.19 980.59±22.11 186.94±5.34 30.68±0.18 80.45±3.05 12 3.76±0.06 495.51±5.34 1047.06±15.12 158.90±25.11 23.42±0.18 96.15±1.12 CK 0 60.97±0.06 1649.27±18.83 5471.2±35.15 6788.8±38.34 100±0.00 -

[1] 尹卓蓉. 葡萄酒活性干酵母的使用方法 [J]. 酿酒, 1989, 16(1):20−23.YIN Z R. Application method of wine active dry yeast [J]. Liquor Making Science & Technology, 1989, 16(1): 20−23.(in Chinese) [2] BATT C A, TORTORELLO M L. Encyclopedia of food microbiology[M]. Oxford, 1999: 2335-2341. [3] 董家武, 李雪松. 国内活性干酵母生产的现状与发展 [J]. 食品科技, 2003, 28(9):7−10,13. doi: 10.3969/j.issn.1005-9989.2003.09.004DONG J W, LI X S. Status and development for production of active dry yeast in China [J]. Food Science and Technology, 2003, 28(9): 7−10,13.(in Chinese) doi: 10.3969/j.issn.1005-9989.2003.09.004 [4] 张建峰, 耿宏伟, 王丕武. 酿酒活性干酵母生产工艺优化及干燥剂的选择 [J]. 食品科学, 2011, 32(9):213−216.ZHANG J F, GENG H W, WANG P W. Process optimization and protective agents for alcohol active dry yeast [J]. Food Science, 2011, 32(9): 213−216.(in Chinese) [5] 陈琪彤. 一株布拉氏酵母高密度发酵与干燥工艺的优化[D]. 武汉: 华中农业大学, 2020.CHEN Q T. Optimization of A high-density fermentation and drying process for A strain of Saccharomyces boulardii[D]. Wuhan: Huazhong Agricultural University, 2020. (in Chinese [6] 孙康, 李军, 张鸣宇, 等. 美极梅奇酵母冷冻干燥复合保护剂的优化研究 [J]. 食品与发酵工业, 2022, 48(11):73−79. doi: 10.13995/j.cnki.11-1802/ts.029656SUN K, LI J, ZHANG M Y, et al. Optimization of freeze-drying compound protective agent for Metschnikowia pulcherrima [J]. Food and Fermentation Industries, 2022, 48(11): 73−79.(in Chinese) doi: 10.13995/j.cnki.11-1802/ts.029656 [7] 李东歌, 刘红艳, 叶冬青, 等. 一种葡萄酿酒活性干酵母简便制备法 [J]. 食品工业科技, 2021, 42(8):133−137. doi: 10.13386/j.issn1002-0306.2020070140LI D G, LIU H Y, YE D Q, et al. A simple preparation method of active dry yeast for wine making [J]. Science and Technology of Food Industry, 2021, 42(8): 133−137.(in Chinese) doi: 10.13386/j.issn1002-0306.2020070140 [8] 周亚男. 鲁氏酵母高密度培养制备及产呋喃酮条件优化研究[D]. 大庆: 黑龙江八一农垦大学, 2018.ZHOU Y N. Optimization of high density culture and preparation of DMHF from Z. rouxi[D]. Daqing: Heilongjiang Bayi Agricultural University, 2018. (in Chinese) [9] 张鸿雁, 王文军, 邓丽莉, 等. 膜醭毕赤酵母真空干燥制剂对热环境耐受力的提高 [J]. 食品科学, 2019, 40(10):112−120. doi: 10.7506/spkx1002-6630-20180511-170ZHANG H Y, WANG W J, DENG L L, et al. Improved tolerance of vacuum-dried Pichia membranifaciens to thermal environment [J]. Food Science, 2019, 40(10): 112−120.(in Chinese) doi: 10.7506/spkx1002-6630-20180511-170 [10] 张鸿雁, 曾凯芳, 周雅涵, 等. 酵母热干燥法及其活性提高途径 [J]. 食品与机械, 2017, 33(2):205−210. doi: 10.13652/j.issn.1003-5788.2017.02.043ZHANG H Y, ZENG K F, ZHOU Y H, et al. Thermal drying methods of yeast and the ways to improve the activity [J]. Food & Machinery, 2017, 33(2): 205−210.(in Chinese) doi: 10.13652/j.issn.1003-5788.2017.02.043 [11] 安峰, 叶京生, 李芳, 等. 流化床吸附干燥酵母醪液的流化特性 [J]. 天津科技大学学报, 2009, 24(6):68−70. doi: 10.3969/j.issn.1672-6510.2009.06.017AN F, YE J S, LI F, et al. Fluidization characteristics of yeast spent solution adsorbed in carrier [J]. Journal of Tianjin University of Science & Technology, 2009, 24(6): 68−70.(in Chinese) doi: 10.3969/j.issn.1672-6510.2009.06.017 [12] 张艳艳. 酱油活性干酵母的制备及应用[D]. 天津: 天津科技大学, 2013.ZHANG Y Y. Preparation and application of soy sauce active dry yeast[D]. Tianjin: Tianjin University of Science & Technology, 2013. (in Chinese) [13] STRASSER S, NEUREITER M, GEPPL M, et al. Influence of lyophilization, fluidized bed drying, addition of protectants, and storage on the viability of lactic acid bacteria [J]. Journal of Applied Microbiology, 2009, 107(1): 167−177. doi: 10.1111/j.1365-2672.2009.04192.x [14] 区伟佳, 王荣, 李华兴, 等. 高浓度大豆生防芽孢杆菌粉剂喷雾干燥微胶囊化工艺研究 [J]. 大豆科技, 2010(3):3−6. doi: 10.3969/j.issn.1674-3547.2010.03.002QU W J, WANG R, LI H X, et al. Technology for micro-encapsulation of high density antifungal entophytic bacteria AF67 by spray drying [J]. Soybean Science & Technology, 2010(3): 3−6.(in Chinese) doi: 10.3969/j.issn.1674-3547.2010.03.002 [15] 陈毛清, 赵华. 葡萄酒活性干酵母的干燥工艺研究 [J]. 酿酒科技, 2006(8):88−90. doi: 10.3969/j.issn.1001-9286.2006.08.023CHEN M Q, ZHAO H. Study on the drying techniques of active dry yeast of grape wine [J]. Liquor-Making Science & Technology, 2006(8): 88−90.(in Chinese) doi: 10.3969/j.issn.1001-9286.2006.08.023 [16] 梁璋成, 任香芸, 林晓姿, 等. 低产尿素、杂醇油红曲黄酒酵母的筛选及鉴定 [J]. 中国食品学报, 2018, 18(2):265−271. doi: 10.16429/j.1009-7848.2018.02.034LIANG Z C, REN X Y, LIN X Z, et al. Screening and identification of the yeast stains with low urea and fusel oil production for brewing in Hong qu(glutinous rice wine) [J]. Journal of Chinese Institute of Food Science and Technology, 2018, 18(2): 265−271.(in Chinese) doi: 10.16429/j.1009-7848.2018.02.034 [17] 苏昊, 梁璋成, 林晓姿, 等. 酿酒酵母高密度增殖酒糟多肽糖蜜培养基优化 [J]. 福建农业学报, 2021, 36(5):610−618. doi: 10.19303/j.issn.1008-0384.2021.05.016SU H, LIANG Z C, LIN X Z, et al. Optimized medium utilizing distiller’s grains polypeptide for high-density culture of Saccharomyces cerevisiae [J]. Fujian Journal of Agricultural Sciences, 2021, 36(5): 610−618.(in Chinese) doi: 10.19303/j.issn.1008-0384.2021.05.016 [18] 中华人民共和国卫生部, 中国国家标准化管理委员会. 食品卫生微生物学检验 霉菌和酵母计数: GB/T 4789.15—2016[S]. 北京: 中国标准出版社, 2016. [19] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. 食品安全国家标准 食品加工用酵母: GB 31639—2016[S]. 北京: 中国标准出版社, 2017. [20] CHEN B Y, LIANG Z C, LIN X J, et al. Enhanced survival of fluidized bed-dried microencapsulated Saccharomyces cerevisiae cells in the presence of Hongqu rice distiller’s grain peptides [J]. LWT, 2022, 163: 113511. doi: 10.1016/j.lwt.2022.113511 [21] HENDERSON S M, PABIS S. GraindryingtheoryI: temperature effect drying coefficient [J]. Journal of Agricultural Research Engineering, 1961, 6: 169−174. [22] WU J, LI L L, WU X Y, et al. Characterization of oat (Avena nuda L. ) β-glucan cryogelation process by low-field NMR [J]. Journal of Agricultural and Food Chemistry, 2016, 64(1): 310−319. doi: 10.1021/acs.jafc.5b03948 [23] 李直, 王丹, 董明盛, 等. 西藏灵菇菌粒、瑞士乳杆菌LZ-R-5与普通乳酸菌的发酵乳特性对比及低场核磁共振在其储藏期间水分的在线监测应用 [J]. 食品工业科技, 2018, 39(21):53−60. doi: 10.13386/j.issn1002-0306.2018.21.010LI Z, WANG D, DONG M S, et al. Comparison of fermented milk characteristics of Tibetan kefir grains, Lactobacillus helveticus LZ-R-5 and common lactic acid bacteria and on-line monitoring application of low-field NMR in storage period [J]. Science and Technology of Food Industry, 2018, 39(21): 53−60.(in Chinese) doi: 10.13386/j.issn1002-0306.2018.21.010 [24] MOMOSE Y, MATSUMOTO R, MARUYAMA A, et al. Comparative analysis of transeriptional responses to the cryo protectants, dimethyl sulfoxide and trehalose, which confer tolerance to freeze-thaw stress in Saccharomyces cerevisiae [J]. Cryobiology, 2010, 60(3): 245−261. doi: 10.1016/j.cryobiol.2010.01.001 [25] 赵雪, 陈超, 王文博, 等. 低场核磁共振分析乳酸菌细胞中水分分布及其变化[J]. 食品与发酵工业. https://doi.org/10.13995/j.cnki.11-1802/ts.032365.ZHAO X, CHEN C, WANG W B, et al. Study on water distribution and variation in lactic acid bacteria using low field NMR [J]. Food and Fermentation Industry. https://doi.org/10.13995/j.cnki.11-1802/ts.032365. (in Chinese) [26] 阮榕生. 核磁共振技术在食品和生物体系中的应用[M]. 北京: 中国轻工业出版社, 2009: 90-94. [27] FU N, CHEN X D. Towards a maximal cell survival in convective thermal drying processes [J]. Food Research International, 2011, 44(5): 1127−1149. doi: 10.1016/j.foodres.2011.03.053 [28] FRANÇA M B, PANEK A D, ELEUTHERIO E C A. Oxidative stress and its effects during dehydration [J]. Comparative Biochemistry and Physiology Part A:Molecular & Integrative Physiology, 2007, 146(4): 621−631. [29] SCHUCK P, JEANTET R, BHANDARI B, et al. Recent advances in spray drying relevant to the dairy industry: A comprehensive critical review [J]. Drying Technology, 2016, 34(15): 1773−1790. doi: 10.1080/07373937.2016.1233114 -

下载:

下载: